Manganese Acetate: From Early Discovery to Modern Applications

Historical Development

Long before high-tech laboratories, researchers experimented with metals and acids, hunting for answers in barrels, beakers, and chance. Manganese acetate traces its roots to Europe’s early industrial age—curiosity about manganese began in the late 1700s as glassmakers searched for stable colors and chemists chased purification methods. Over decades, researchers learned manganese reacts neatly with acetic acid, forming a compound that distills both medicine and metallurgy’s drive for useful materials. Large factories crept up in the 20th century, finding steady demand from printing, textiles, and plastics, and manganese acetate started appearing in research papers on catalysts and organic synthesis. Today, production follows strict environmental rules; back then, simplicity won the day: a basic reaction in glassware, dried, pressed, and sold to whoever needed it—factories, universities, innovators. This blend of discovery and practical use built a foundation for the material’s commercial rise.

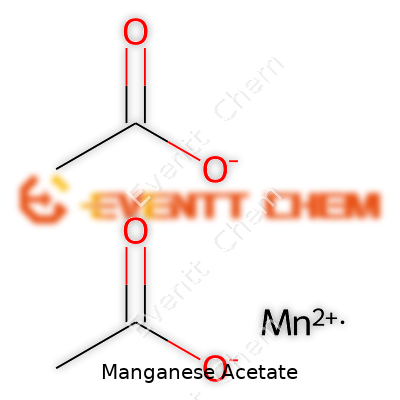

Product Overview

Manganese acetate looks pretty nondescript: a pinkish or rose powder that dissolves well in water, less so in alcohol. Most people don’t realize it’s a backbone ingredient for everything from dryer sheets to fuel additives. Factories around the world churn out thousands of tons each year. Manufacturers demand different grades—ultrapure for electronics, technical grade for dye and pigment making, agriculture, or catalyst formulation. Its standard form comes as dihydrate, though anhydrous types exist for specialty needs. Packaging workers scoop, seal, and ship it in drums or bags, sticking close to demands for safety and moisture control since the powder pulls water from air. Product labeling includes batch traceability, content verification, and detailed hazard information.

Physical & Chemical Properties

This compound doesn’t hide its hand—chemical formula Mn(CH3COO)2.2H2O, molecular weight sits around 245.09 g/mol with the locked-in water molecules. As a solid, it won’t impress visually: a rose or lavender powder that cakes in open air due to its hygroscopic bite. It melts around 80°C, decomposes before boiling, and leaves behind a sticky mess of water and manganese oxides. Its water solubility makes it easy to use in wet chemistry, and acid-base reactions or oxidative procedures often call for it in solution. Its paramagnetic property sticks out in lab work—magnetism tells scientists there’s more going on inside those tiny pink crystals.

Technical Specifications & Labeling

Each batch arrives with a certificate showing key numbers: at least 98% Mn(CH3COO)2.2H2O by weight, often less than 0.1% iron, and stringently low chloride and sulfate impurities. Water content—and how much sticks to the powder—gets tracked by Karl Fischer titration or oven drying. Modern labs and industrial users look closely at these numbers before ordering, since catalysis, batteries, or analytical work can go sideways if impurities sneak through. Labeling meets global standards, listing chemical name, hazard symbols, production date, recommended storage, and any relevant REACH or OSHA compliance details. In my own work, missing or ambiguous labels slow projects, so accurate, consistent labeling never earns complaints.

Preparation Method

Preparation sounds simple on paper: add manganese carbonate or dioxide to glacial acetic acid, stir under heat, filter, and recover crystals by slow evaporation. Industrial plants scale this up, optimizing temperature and reaction time for big batches and adjusting washing steps to limit contamination. Crystallization deserves care: quick cooling traps impurities, slow cooling gets better purity and larger crystals. Once dry, the material goes straight to mills for size adjustment. Years ago, a colleague and I improvised a batch in a student lab—reactants fizzed, the air stung of vinegar, the final powder climbed out of solution in a pink crust. We learned patience matters: rushing skipped purity checks, leading to a sticky, useless end product.

Chemical Reactions & Modifications

Manganese acetate’s main appeal lies in its versatility. The compound enters organic reactions as an oxidizing agent or catalyst, making possible the creation of esters, alkenes, or more complex molecules. Heating with other metal salts turns out new coordination compounds, each with their own magnetic or optical quirks. In battery research, manganese acetate gets converted to manganese oxides—essential for lithium-ion and alkaline batteries—by simple heat treatment under air. In textile dyeing, the acetate helps drive color fixation by bridging chemical bonds between fibers and dyes. Tinkering with the molecule under controlled conditions, researchers can trade out the acetate for other carboxylates, building custom catalysts that unlock new synthetic pathways and treatments.

Synonyms & Product Names

Chemists and industry folk call it various names: manganese(II) acetate, manganous acetate, or just “Mn-acetate.” Across safety documents and catalogs, names can shift, but labeling across regions stays clear. In Europe, “Acetic acid, manganese(II) salt, dihydrate”; in older American texts, “Manganous acetate” appears. CAS number 6156-78-1 traces a batch’s registration history from raw chemical inventory to approved product on a client’s shelf. Commercial brands sell it under proprietary trade names, yet the molecule stays the same.

Safety & Operational Standards

Safety matters more than ever, and for good reason. Manganese acetate deserves respect: inhaled dust or repeated skin contact can irritate and, over long periods, chronic exposure to manganese risks nervous system health. Working with the material calls for eye protection, dust masks, gloves, and good ventilation. Staff monitor incoming and stored powder for clumping or spills, handle cleanup with negative pressure vacuums, never dry-sweep, and treat all waste as hazardous. Regulatory compliance now tracks worker exposure in real time, reviewing air and surface samples, and training everyone on the risks. In the early days, safety culture lagged behind knowledge; today, companies invest in training, air monitoring, and access controls to ensure workers stay healthy. Even storage isn’t left to chance—cool, dry, well-ventilated rooms prevent caking and dust buildup.

Application Area

Demand for manganese acetate stretches far. In textile factories, it sets dyes on fabrics. Paint and pigment manufacturers use it as a desiccant and catalyst, drying linseed oil quicker and producing durable finishes. Laboratories employ it for oxidation reactions in organic synthesis, especially in pharmaceuticals where pure manganese acetate helps create disease-fighting molecules. In battery production, the compound transforms to manganese oxides, supporting energy storage for electric vehicles, power tools, and backup grids. Fuel additive makers run the acetate through additional reactions to curb engine knocking, cleaning up emissions. Research teams dig deeper: in catalysis, coordination chemistry, PET manufacturing, or water treatment, manganese acetate opens doors to new processes and materials. My own work relied on its reliability in controlled oxidation reactions, delivering cleaner yields and more predictable results than cheaper, less pure alternatives.

Research & Development

Across global labs, manganese acetate gets a fresh look every year. Chemists replace or modify the acetate to form more specialized manganese compounds, optimizing everything from reaction speed to selectivity. In battery research, switching up synthesis routes—hydrothermal, sol-gel, or microwave-driven processes—delivers nanostructured materials with enhanced conductivity, tailored for high-capacity electrodes. Textile researchers adjust ratios and processing temperatures, driving more efficient color fixation and novel fiber treatments. Advanced manufacturing firms ask for manganese acetate with ever-tighter impurity limits, pushing supply chains toward better quality control and real-time analytics. In my experience, projects succeed or fail based on the reliability of their building blocks—products like manganese acetate deliver a foundation for innovation when they come documented, consistent, and traceable.

Toxicity Research

Scientists keep a close watch on manganese exposure. Inhalation or repeated skin contact raises risks—from acute irritation to chronic effects like manganism, a neurological disorder seen in overexposed workers. Rodent studies link high doses to reproductive and developmental harm. Decades of research shape strict occupational exposure guidelines: OSHA, NIOSH, and the EU each set differing but steadily tightening limits for air, water, and soil. Toxicology tests now extend to all stages: manufacturing, use, and disposal. Companies invest in engineering controls and personal protective equipment, running regular health surveillance and environmental assessments. Work involving children’s products, food, or drinking water triggers additional scrutiny. Wastewater from factories processing manganese acetate must meet discharge limits, driving research into efficient, closed-loop recycling and treatment. My own industry contacts share concerns about rising costs associated with tighter standards, but recognize these steps protect workers, communities, and company reputations.

Future Prospects

Interest in manganese acetate keeps growing. The global transition toward renewable energy needs better batteries, so manufacturers keep scaling up manganese oxide production routes, drawing on new chemistry and old reliability. Demand spikes drive investment in cleaner, safer production, and the pressure continues to deliver more sustainable supply chains. Startups and research teams chase new applications in medical imaging, green catalysis, and water treatment, focusing on modifying the material or blending it with novel supports. Regulatory changes will likely prompt even lower limits on heavy metal contaminants, propelling advances in purification and monitoring. As the planet pivots toward lower-carbon economies, the role of manganese acetate—quiet but essential—will keep expanding, carried by diligent science, vigilant safety, and a community of researchers, engineers, and manufacturers committed to progress.

What People Use Manganese Acetate For

A lot of folks don’t realize just how often manganese acetate shows up in everyday products and processes. It has a long name, but its uses land closer to our routines than you'd think. Years ago—working in a small paint shop—I learned that this pink crystal was more than a dusty bottle on a shelf. Our chemist relied on it to make dyes bond properly, giving paint its long-lasting color. Textile manufacturers use the same chemical as a fixative. Without it, fabrics would lose color in a handful of washes.

The chemical industry puts manganese acetate to work as a catalyst. It helps kickstart vital reactions in making polyesters and other plastics. According to a 2021 Royal Society of Chemistry report, manganese acetate keeps reaction costs down and productivity high. That means cheaper, stronger packaging for everything from water bottles to food wrap.

Environmental Science—and Cleaner Air

Catalysts aren’t just for factories churning out consumer goods. Environmental labs use manganese acetate for air quality testing and water treatment. Researchers combine it with permanganate to break down dangerous chemicals. You can see this at work in the cleanup of toxic spills or factory runoff. Today, this chemical has a role in making our air and water safer.

One example—diesel exhaust. Scientists have found that manganese acetate helps sensors detect nitrogen oxides more easily. These sensors allow trucks and buses to meet pollution standards. Cleaner air, especially near highways, improves public health. Studies cited by the Environmental Protection Agency highlight fewer asthma attacks when emission controls work as intended.

Batteries, Electronics, and Research Labs

Every time you check your phone or use a wireless device, you’re part of a battery-powered world. Manganese has always mattered in battery chemistry—zinc-carbon and alkaline batteries need it for reliable power. Recent advances in lithium-ion technology use manganese acetate as a key ingredient for stable electrode materials. This helps your phone charge faster and last longer.

Beyond battery tech, I’ve seen university labs lean on manganese acetate to prepare metal complexes for electronics research. It holds value for scientists testing new semiconductors or studying materials with unique magnetic properties.

Risks, Solutions, and Responsible Practice

Like any chemical, manganese acetate demands respect. In commercial labs and factories, regular training keeps workers safe. This includes gloves, eye protection, and plenty of ventilation. Accidental spills call for fast cleanup; manganese acetate can irritate the skin and lungs, so knowledge of safe handling matters.

Disposal also deserves attention. Pouring waste down the drain risks polluting rivers and groundwater. More companies now recycle or treat manganese residues, following strict environmental rules. Tech giants such as Tesla and Panasonic back recycling as they chase greener batteries.

Better alternatives and process improvements help cut down on risks too. Research teams regularly share safer methods for using and neutralizing manganese acetate at chemical conferences and in academic journals. These practical steps keep both people and planet in mind.

Why This Matters to All of Us

As someone who’s swapped stories with paint shop workers and watched researchers hunt for safer procedures, it’s clear that manganese acetate sits at a crossroads of convenience and responsibility. Whether brightening shirts, cleaning up emissions, or powering the next phone, it carries both promise and responsibility. Paying attention to how we use and dispose of chemicals like manganese acetate ensures progress doesn’t outpace safety or environmental care.

Breaking Down the Basics

Manganese acetate’s chemical formula looks like this: Mn(CH3COO)2. Lab folks often use its tetrahydrate version, which adds four water molecules, so you might spot it listed as Mn(CH3COO)2·4H2O. This bit of chemistry means the compound contains one manganese atom and two acetate groups, each made from two carbons, three hydrogens, and two oxygens. Toss in four water molecules, and you have the full picture scientists rely on during experiments.

Why Does It Matter?

Many people see big, confusing formulas and zone out. I’ve done it plenty of times. But this stuff shows up in surprising places, far outside the lab. Paint makers use manganese acetate to help dry oil-based products. It acts as a catalyst, making colors last longer on walls or metal.

Manganese, the centerpiece of this formula, plays a huge role in human health. Small amounts help our bodies process cholesterol, form bones, and heal wounds. Factories use manganese acetate to produce other chemicals, batteries, and ceramics. Without a proper formula, experts run into real trouble scaling up manufacturing or guaranteeing product quality.

Trust Through Transparency

Giving accurate chemical formulas keeps buyers and users safe. You’ll see this anytime you check a product sheet from a reputable supplier: clear details on chemical makeup, safety precautions, and even storage guidelines. Skipping over those details can lead to mistakes. Years back, I watched a novice technician confuse manganese acetate with manganese sulfate. Similar names, totally different uses, and the slipup nearly kept a whole batch of ceramic glaze from meeting safety tests. The mix-up brought home how critical clear communication and chemical literacy are for new workers and old hands alike.

Questions of Purity and Contamination

Quality control experts measure out these precise formulas to keep contamination at bay. Impure chemicals throw off experiments, yield unpredictable results, or put users at risk. For example, road engineers sometimes use manganese acetate while studying salt alternatives for de-icing. If a formula isn’t followed to the letter, results steer public agencies in the wrong direction—wasting funds and adding hazards to winter driving. Rigorous attention to the formula, down to every hydrate, can make all the difference in these fields.

Making Science More Approachable

Science takes on a whole new meaning once you realize how something like Mn(CH3COO)2 becomes part of household projects and public infrastructure. If people get more familiar with chemical shorthand, they start asking smarter questions, spotting issues, and making better decisions at work and home. I’ve seen companies run training sessions on chemical formulas and watched morale go up—suddenly, everyone in the building shares a language that keeps them safer and helps avoid expensive blunders.

Solutions Lying in Better Collaboration

Teaching kids and adults basic formulas like manganese acetate’s could boost confidence and responsibility in chemistry-intensive industries. Pairing practical hands-on training with digital resources ensures better retention and smarter workplace behaviors. Throwing a formula on a dusty shelf helps nobody. The more visible and familiar these building blocks become, the easier it gets to solve problems, spark curiosity, and keep technology moving forward responsibly.

Getting to Know Manganese Acetate

Manganese acetate crops up in chemistry labs and certain manufacturing settings. This salt of manganese and acetic acid shows up as pink crystals. Some use it in dyeing cotton, making chemicals, or as a catalyst. Materials like this live on supply shelves, not in kitchen pantries, for a reason. I’ve watched people handle it in research spaces: you see goggles, gloves, and no eating lunch nearby. That precaution speaks volumes about its risks.

What Science Says About Its Risks

Workers and lab students come across safety sheets telling them manganese acetate can cause a sore throat, coughing, or even shortness of breath if you breathe it in. I’ve seen the warnings that skin or eye contact triggers irritation. Most health handbooks group manganese compounds together. Extended exposure, especially in dust form, has led to serious concerns about manganism—a nervous system disorder. The CDC points out that symptoms resemble Parkinson’s, with slow movement and shaking.

A fact that everyone should pay attention to: manganese itself is an essential mineral. Our bodies need it for bones and metabolism, but only at trace levels. Too much—no matter the source—spells trouble. The Environmental Protection Agency (EPA) has placed manganese on lists regulating safe handling and discharge, to ensure no one downs dangerous amounts in water. Public health experts tell us to respect those limits.

Focusing On Industrial Exposure

People using manganese acetate often don’t run into it day-to-day; it stays locked away in bulk chemical containers, not household products. Factory workers or researchers, though, risk exposure whenever batches get mixed or crystals form dust. Many of us take for granted that factory exhausts and wastewater go through treatment. Without that, manganese compounds could reach rivers and soil. Certain plants can take up excess manganese—toxic for them, too, once the scales tip.

I’ve seen facilities where good ventilation, closed handling systems, and full gear (think gloves and masks) minimize risk. Clean work habits—washing hands frequently, swapping out dirty lab coats—make a difference. Employers following OSHA (Occupational Safety and Health Administration) rules cut down incidents drastically. Where rules slip, workers face headaches, lung irritation, or worse.

Handling Clean-Up and Disposal Wisely

Disposal of manganese acetate isn’t just tossing it in the trash. Safe chemical disposal demands segregation and proper contracts with disposal firms. Water authorities keep close tabs on waste streams, understanding that even trace contamination builds up. Chemical recycling grows in interest, so that spent manganese compounds can sometimes rejoin industrial use, cutting raw material waste. I’ve heard colleagues push for better monitoring and treatment tech, so less of any metal compound slips through city treatment plants.

Better Training and Transparency

Anyone who works with chemicals learns early: hazard labels and up-to-date safety data sheets matter. Manganese acetate deserves no shortcuts. Safety training for staff, students, and even custodians cleaning up labs prevents accidental splashes or dust clouds. Publicly shared environmental records let neighbors know that local air and water stay clear. It’s on employers, teachers, and public agencies to provide honest, clear information—no technical mumbo-jumbo burying the facts.

Practical talk: most people rarely face direct risk from manganese acetate. Folks in industry do need strong safety protocols and enforced oversight. Removing sludge or powders in well-designed facilities puts both employee health and environmental protection upfront. That mix—strict workplace rules, steady public oversight, and personal care—keeps issues with manganese compounds in check.

Understanding What You’re Working With

Manganese acetate doesn’t shape headlines, but it deserves attention from anyone handling chemicals. It doesn’t puff up or explode, yet it can cause skin and eye irritation or trouble breathing if you don’t keep it in check. My own days in the lab taught me that a moment’s slip during storage leads to ruined samples, emergency calls, and a permanent mark on your safety record. Proper storage isn’t busywork—it’s peace of mind and prevention rolled into one.

Good Storage Starts with the Right Container

I learned fast that original packaging matters. Loose caps, makeshift jars, or unlabeled bags spell disaster for any chemical. For manganese acetate, stick to airtight, robust containers. Polyethylene, glass, or high-density plastics hold up best. Avoid metal containers. Residue moisture reacts with the acetate and metal, leading to contamination or a gummy mess. Always mark your containers with a clear label—product name, date received, hazard information. The clearest label wins the race when confusion strikes during inventory checks or emergencies.

Controlling the Environment

Any chemical shelf collects more than just dust. Manganese acetate breaks down under direct sunlight or high heat. If you’ve ever reached for a reagent, only to find a crystallized lump or changed color, you know how frustrating inadequate storage gets. Aim for dry, ventilated rooms well away from heat sources: no radiators, no sunny windows. Humidity pushes moisture into your container, which isn’t just a purity issue—the compound can cake up or leach out.

Distance Means Safety

My own workspace separated reagents by hazard class long before it was a requirement. Manganese acetate sits best away from acids, bases, and oxidizers. I once saw a whole shelf of chemicals rendered useless (and the office air reeking for a week) when someone stashed organic solvents and a box of oxidizers together. Most accidents I’ve seen happen during storage. Invest time organizing now, and you save time—and stress—down the road.

Security Matters

Storing the chemical in a locked cabinet restricts access. Whether it’s a shared university lab or a small manufacturing space, only trained staff need the key. Small lapses end with spills, exposure, or costly inventory loss. It’s much easier to give a two-minute lesson on secure storage than to explain a preventable incident to management or safety inspectors.

Personal Protection and Cleanliness

Routine builds safety into your work. Gloves, goggles, and lab coats aren’t overkill; they make accidents highly unlikely. Clean up spills immediately, and never let waste pile up. Store clean tools with your chemicals, and make sure everyone knows the cleanup protocol. I keep a written checklist taped to storage doors: it’s not just for new hires—sometimes I catch myself needing the reminder during busy stretches.

Waste Management and Disposal

Expired or tainted manganese acetate shouldn’t sit forgotten in storage. Proper hazardous waste disposal keeps your workplace safe and legal. Use local regulations as a guide. Document everything—dates, reasons for disposal. Accountability cuts down on mistakes, and it stands up to any external audit or in-house review.

Why It’s Worth the Effort

Every container handled with attention spares you from preventable headaches. Even in the busiest work setting, good habits last. Storing manganese acetate with respect for its properties and hazards keeps people safe, shelves organized, and operations running smooth. From one set of steady hands to another, the effort put into careful storage always pays off in the end.

Appearance and Texture

Manganese acetate typically forms a pinkish or pale red solid that catches the eye, especially compared with the gray-black look of pure manganese metal. The color owes itself to the manganese(II) ion, which also explains why this salt stands out on a shelf of white and off-white chemicals. In most labs, manganese acetate comes as a crystalline powder or small chunky pieces that feel dry and gritty between the fingers. This material doesn’t clump up under regular room humidity – a plus for those who need to weigh or transfer it without fuss.

Solubility and Behavior in Water

In water, manganese acetate dissolves quickly, making a clear, pink solution. I remember trying to mix it into cold water during an undergrad experiment, and the powder simply vanished after a quick swirl. This high solubility sets manganese acetate apart from other manganese compounds, such as the oxide or carbonate, which stay gritty and barely dissolve. Because of this trait, chemists often pick manganese acetate when they need a liquid form of manganese for reactions or solutions.

Melting Point and Thermal Stability

This salt starts breaking down before it can melt freely. Heating manganese acetate drives off its crystal water content (if it’s a hydrated form) pretty quickly – usually by 100°C to 150°C – leaving a drier, whiter version behind. If the temperature keeps rising, the material eventually decomposes, giving off acetic acid fumes and leaving manganese oxides that look brown or black. Any lab using it near a flame quickly notices the strong vinegar smell coming from the acetic acid vapor. In my own lab comfort, I prefer using a ventilated hood when heating any acetates.

Density and Handling

Manganese acetate sits close to 1.6 g/cm³ in density, similar to many common salts. This means small scoops don’t weigh as much as denser metals or oxides – so accurate weighing is essential when quantities need to be precise. The powdery crystals can leave pinkish stains, so neat handling pays off. Wearing gloves and keeping a tidy bench helps avoid mess and skin contact.

Stability in Storage

One positive about manganese acetate: It doesn’t react with normal room air or moisture, so storing it in a sealed jar in a cool, dry spot prevents caking and impurity buildup. I've stored it for months without noticing any problems. The main risk sits in mixing it with strong oxidizers or acids, since those combos can trigger unwanted reactions or corrosion. A simple amber bottle on a standard chemical shelf keeps things safe and manageable.

Why Physical Properties Matter

These physical properties determine how manganese acetate gets used in real-world scenarios. Its easy solubility means it’s often a choice for catalysis work, textile dyes, or lab preparations where manganese needs to be in solution. Its distinct color makes it easy to track and helps detect cross-contamination. The low melting and decomposition points mean extra care is necessary when heating or storing near hot equipment. All these features affect safety planning, equipment choices, and experiment success. In industries or classrooms where safety and efficiency matter, knowing these basic physical facts helps people make better decisions while working with this material.

| Names | |

| Preferred IUPAC name | manganese(II) acetate |

| Other names |

Acetic acid, manganese(2+) salt

Manganese(II) acetate Manganese diacetate Manganese(II) ethanoate |

| Pronunciation | /ˈmæŋ.ɡəˌniːz ˈæs.ɪ.teɪt/ |

| Identifiers | |

| CAS Number | 6156-78-1 |

| Beilstein Reference | 1901407 |

| ChEBI | CHEBI:31506 |

| ChEMBL | CHEMBL185181 |

| ChemSpider | 51819 |

| DrugBank | DB14545 |

| ECHA InfoCard | 100.029.188 |

| EC Number | 231-869-6 |

| Gmelin Reference | 85359 |

| KEGG | C01438 |

| MeSH | D008345 |

| PubChem CID | 8892 |

| RTECS number | OO9275000 |

| UNII | J5L7VA5E5A |

| UN number | UN2813 |

| CompTox Dashboard (EPA) | DTXSID0052112 |

| Properties | |

| Chemical formula | C4H6MnO4 |

| Molar mass | 173.04 g/mol |

| Appearance | Pink powder or crystals |

| Odor | Acetic odor |

| Density | 1.59 g/cm³ |

| Solubility in water | Soluble |

| log P | -2.38 |

| Vapor pressure | Negligible |

| Acidity (pKa) | 7.2 |

| Basicity (pKb) | 7.36 |

| Magnetic susceptibility (χ) | +1300·10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.472 |

| Dipole moment | 9.42 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 204.5 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -815.6 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -1120.8 kJ/mol |

| Pharmacology | |

| ATC code | A12CC03 |

| Hazards | |

| Main hazards | Harmful if swallowed; causes skin and eye irritation; may cause respiratory irritation. |

| GHS labelling | GHS02, GHS07 |

| Pictograms | GHS07,GHS09 |

| Signal word | Warning |

| Hazard statements | H302: Harmful if swallowed. |

| Precautionary statements | P264, P270, P280, P301+P312, P330, P501 |

| NFPA 704 (fire diamond) | Health: 2, Flammability: 1, Instability: 0, Special: - |

| Autoignition temperature | Not autoignitable |

| Lethal dose or concentration | LD50 oral (rat): 1,750 mg/kg |

| LD50 (median dose) | LD50 (median dose): Oral rat LD50 = 1750 mg/kg |

| NIOSH | MW3675000 |

| PEL (Permissible) | 5 mg/m3 |

| REL (Recommended) | No recommended exposure limit |

| IDLH (Immediate danger) | 500 mg/m3 |

| Related compounds | |

| Related compounds |

Manganese(II) chloride

Manganese(II) sulfate Iron(II) acetate |