Magnesium Acetate Tetrahydrate: Insights and Perspectives

Historical Development

The story of magnesium acetate tetrahydrate winds back hundreds of years, built on a foundation of curiosity about salts and their roles in daily life. Early chemists learned to isolate magnesium compounds from minerals and brine, aiming to understand these white, crystalline substances that often appeared in the ashes of burned plants. Scientific records describe magnesium’s journey into the hands of the medical and textile industries, where magnesium acetate played a supporting role in dyeing processes and as a catalyst in organic chemistry. Modern production gained momentum during the industrial age, as precise analytical techniques unlocked a clearer picture of the salt’s molecular structure, helping push laboratory and production standards further than ever before. Each shift in chemical manufacturing brought subtle but important tweaks to quality protocols, impacting everything from the purity of the final product to safety thresholds in the workplace.

Product Overview

Magnesium acetate tetrahydrate, a crystalline salt, stands out for its ability to blend easily into solutions, its solubility, and a reliable availability as a technical, analytical, and pharmaceutical-grade ingredient. Chemists favor it for tasks requiring delicacy and predictability, like buffer solutions and as a catalyst in reactions involving complex organic molecules. In industry workshops, technicians measure and mix magnesium acetate into fabric treatment baths, personal care formulas, and food applications. The salt’s non-volatility and stable shelf life minimize risks both in handling and in storage environments, reducing waste and insurance costs for bulk buyers. Recognized under several product codes and purity grades, this salt has found its way from small laboratory stocks all the way to mass commodity shipments in countless warehouses.

Physical & Chemical Properties

Magnesium acetate tetrahydrate appears as clear, colorless, odorless crystals that feel cool and slightly slippery between the fingers. Each crystal hosts four molecules of water for every unit of salt, which delivers excellent solubility in water and a lower risk of dust formation during handling. It melts at temperatures just above 80°C, breaking down before boiling begins, and releases vapors that should always be avoided for safety. With a molecular weight hovering near 214 g/mol, magnesium acetate breaks down completely in water, freeing up magnesium ions ready for crosslinking, buffering, or neutralizing acids. Laboratory tests confirm a pH near 7 in dilute solution, making it compatible with a wide array of biological and chemical processes. The absence of hazardous organic residues provides confidence for applications in sensitive environments, such as laboratories, hospitals, and food-processing sites.

Technical Specifications & Labeling

Detailed labeling and documentation have become a norm in modern supply chains. Each batch of magnesium acetate must meet standards set by national and international authorities, such as USP, EP, or food grade certifications. Manufacturers provide certificates stating the magnesium content, water of crystallization, heavy metal content, and residual solvents, which buyers scrutinize before authorizing use. Product containers bear hazard statements, GHS pictograms, lot numbers, and manufacturing dates, while technical data sheets describe the conditions for proper storage—usually cool, dry, and away from sources of ignition or acid fumes. Packaging, often in sealed polyethylene bags or high-density drums, shields against environmental moisture, preserving product quality from the factory floor to the final application point.

Preparation Method

Several routes yield magnesium acetate tetrahydrate, but the preferred method marries magnesium oxide or magnesium carbonate to acetic acid under controlled temperature and pressure. Reactions typically proceed in glass-lined tanks to avoid unwanted reaction byproducts and to simplify purification. The mixture gets filtered, often multiple times, with precise evaporation steps to draw out beautiful crystalline masses. Large-scale operations adjust concentrations and cooling rates to ensure even crystal growth, reducing the risk of dry caking or uneven solvation during dissolution steps. Afterward, workers separate wet crystals and dry them in temperature-controlled ovens, striving for uniform water content and low residual acidity. The consistency of this process supports a level of reliability hard to match with more complex synthetic routes.

Chemical Reactions & Modifications

This salt takes part in a variety of chemical reactions. It reacts with strong acids to release acetic acid and the corresponding magnesium salt—a feature that helps in making specialty pharmaceuticals and food-safe preparations. It catalyzes many organic transformations, encouraging acetylation or transesterification, especially under laboratory conditions. Magnesium acetate also feeds into research on green chemistry, as it does not introduce heavy metals or toxic intermediates into waste streams. Researchers often tweak the molecule or combine it with other agents to investigate new anti-static materials, biodegradable packaging films, and pH-stabilizing additives. Its reliability in synthetic protocols earns a regular place on chemical inventories and process flowcharts worldwide.

Synonyms & Product Names

Depending on context, people call this chemical magnesium ethanoate tetrahydrate, E262, magnesium diacetate, or magnesium acetate four-hydrate. Regulations, supply catalogs, and international trade require strict consistency, but regional preferences and historic conventions sometimes blur the lines. In food processing, E262 refers to both magnesium and sodium acetate salts, so purchasers must check product data to avoid costly sourcing errors. Common suppliers brand the product with proprietary or house-standard names, sometimes including suffixes like “reagent grade”, “analytical grade”, or “pharma grade”, which reflect the rigorousness of their own testing protocols. These distinctions matter wherever contamination, impurity profiles, or regulatory compliance could spell the difference between a successful run and a failed batch.

Safety & Operational Standards

Safety takes center stage every time bags of magnesium acetate arrive on a loading dock. Although the salt itself poses low acute toxicity, fine dust can irritate eyes, skin, or lungs, especially in poorly ventilated spaces. Handlers rely on personal protective equipment—gloves, goggles, dust masks—to minimize direct contact, while air extraction systems keep workplace concentrations far below recommended exposure limits. Training helps workers respond to spills, which get swept or wet-mopped before entering drains, to stop environmental contamination. SDS documentation outlines fire hazards, safe disposal routes, and first aid measures—a prime concern given that washing hands and avoiding accidental ingestion prevent most risks. Workplaces invest in regular audits and compliance checks to ensure product use falls within legal and ethical guidelines.

Application Area

Few laboratory shelves lack a bottle of magnesium acetate, given its contribution to everything from chromatography to molecular biology. Biochemists rely on this salt to stabilize DNA and RNA, maintaining enzyme activity and buffer quality for long sequencing runs. Textile producers use it to fix dyes, controlling the binding of pigments to plant or synthetic fibers and improving color fastness under home laundering conditions. Food science labs reach for magnesium acetate as a flavor enhancer, preservative, or mineral fortifier in specialized dietary supplements. Its gentle alkalinity and reliable behavior support water treatment facilities and environmental monitoring stations. From cement accelerants in construction sites to specialty glass production, the reach of magnesium acetate extends into the bones of modern infrastructure and the finer details of pharmaceutical manufacturing.

Research & Development

Cutting-edge chemical research searches for new ways to harness magnesium acetate’s properties, pushing beyond the comfort zone of basic industrial chemistry. Teams investigate it for use in biodegradable plastics, where its presence tweaks mechanical strength and promotes controlled water uptake. Battery developers test magnesium acetate for safe, non-toxic electrode materials and as a buffer in high-performance electrolytes, looking for safer alternatives to traditional salts. Biotechnologists blend it with other acetates or organic buffers, studying impacts on enzyme stability, protein crystallization, and fermentation yields. Each new publication or patent filing expands the known universe, putting yesterday’s side character into today’s starring role as scientists reimagine greener, less resource-intensive products.

Toxicity Research

Scientific panels agree that magnesium acetate tetrahydrate exhibits low toxicity to humans and animals at doses far above those used in industrial or food contexts. It does not bioaccumulate nor break down into hazardous metabolites, though unintentional eye contact or dust inhalation can cause transient discomfort. Toxicology studies show that rodents tolerate high oral doses without chronic health effects, but regulatory authorities maintain strict guidance on maximum daily intake and environmental discharge specifics. Real-world incidents remain rare, but the risk of dermatitis or mild gastrointestinal symptoms warrants clear labeling and prompt incident response protocols. Environmental scientists keep watch over effluent streams, confirming that magnesium ions and acetate residues break down in municipal treatment systems without threatening aquatic life or soil health.

Future Prospects

As industries migrate toward cleaner production and eco-friendly ingredients, magnesium acetate tetrahydrate stands ready to answer new demands. The salt’s compatibility with food, pharmaceutical, and environmental standards makes it a likely candidate for next-generation additives, bio-based packaging, and sustainable agriculture products. Research partnerships between government, academia, and business focus on scaling up cost-effective, low-waste production techniques, which could push prices down and quality up for everyone involved. Magnesium acetate’s renewable sourcing potential and safe disposal profile align well with tighter global regulations and consumer preference for products with a lighter ecological touch. Looking ahead, the adaptability and safety margin of magnesium acetate tetrahydrate promise a future filled with ongoing discovery, as each generation of chemists, engineers, and entrepreneurs finds new opportunities hidden within those modest, white crystals.

Getting Beyond the Lab Coats

Magnesium acetate tetrahydrate doesn’t grab headlines. Most people never hear its name outside a chemistry class. Out in the real world, this powdery compound often hides inside everyday products and processes, playing an important role behind the scenes. Plenty of folks in food, medicine, and industrial fields know it as a go-to helper — mainly because it brings magnesium to the party in a form that’s easy to handle and mixes well.

Keeping Industry Running

De-icing highways each winter, city crews sprinkle calcium or magnesium salts, and here magnesium acetate does heavy lifting. This stuff works as an alternative to the usual road salts, and it’s less corrosive to concrete and steel. In big cities or places sensitive to environmental damage, crews choose magnesium acetate to help prevent rust on bridges and guardrails. I’ve seen firsthand how metal fixtures last longer in Midwest towns that swapped it in, which saves money over time on repairs.

On the technical side, textile finishing plants rely on it to help cotton fibers absorb dyes more evenly. I have close friends in the dye industry who talk about the headaches avoided by using magnesium acetate for color control. It makes the process cheaper and reduces rejected batches of fabric — a real cost saver.

Makes a Better Food Product

Food makers aren’t just worried about flavor. They spend time choosing the right ingredients for safety and nutrition, too. Magnesium acetate shows up as a food additive, offering a way to enrich products with magnesium. This mineral helps nerves and muscles work properly, and many people fall short of recommended intakes. Adding it to food boosts magnesium content without changing taste.

It also acts as a preservative in some baked goods and dairy, helping to keep molds and spoilage at bay. There’s less waste on grocery store shelves, and consumers get more reliable products.

Health and Lab Value

Medical labs frequently need magnesium for chemical tests and solutions. Magnesium acetate dissolves easily in water, so technicians lean on it for precise magnesium content in buffer solutions or cell cultures. Pharmacists sometimes use it as a supplement for patients who can’t take pills or standard magnesium forms due to sensitivities. The ingredient has a firm safety track record.

Cleaner Air and Water

Magnesium acetate tackles another modern headache — pollution. Factory smokestacks release sulfur dioxide, causing acid rain. Adding magnesium acetate to treatment systems reduces harmful gas emissions. In my hometown, environmental cleanup efforts often list this chemical as a reliable tool in their toolkit to capture pollutants before they escape.

Moving Toward Safer Processes

Plenty of industries want to move away from harsh chemicals that hurt the environment. Magnesium acetate’s relatively low toxicity gives it an edge, especially in sensitive spaces like schools or hospitals. In the cleaning world, it’s used for eco-friendly products that meet high safety standards without stinging eyes or harming skin.

Better Choices for the Future

People expect safer products and less environmental impact from manufacturing. Magnesium acetate offers a practical option that meets both demands. While it’s not glamorous, it steps in quietly where it counts — making everyday items better, helping cities last longer, and keeping processes clean. That blend of usefulness and safety pushes the conversation forward, showing that everyday upgrades can make a difference.

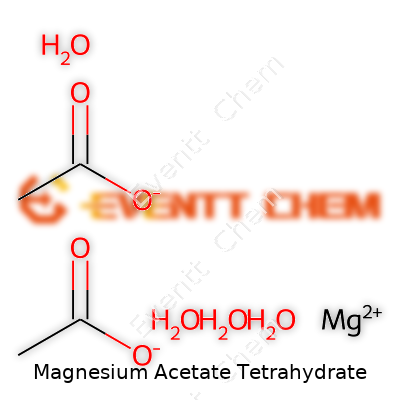

Understanding Its Formula

Magnesium acetate tetrahydrate comes with the chemical formula Mg(CH3COO)2·4H2O. The magnesium ion pairs with two acetate groups, each of which features a methyl and a carboxyl group, and four water molecules attach themselves as hydrates. That’s the textbook definition, but this formula means more than just numbers and letters on a bottle. Every detail in that formula points to how this compound works and where it fits into daily use, from lab experiments to practical applications in environmental cleanup and industry.

Why Formula Precision Matters

The right formula acts as a passport for any chemical, and with magnesium acetate tetrahydrate, the hydration part matters just as much as the acetate. I remember the confusion a rookie might face, getting magnesium acetate anhydrous instead—the lack of water actually changes the compound’s weight, behavior, and how it reacts with other substances. Teachers point this out early in science labs, but in actual jobs, even seasoned chemists double-check labels to avoid mistakes. That extra water in the tetrahydrate version influences how it dissolves and reacts. Practical work in water treatment or food chemistry banks on that predictable solubility and reactivity.

Everyday Applications and Uses

Magnesium acetate tetrahydrate often ends up in classrooms, making buffer solutions for experiments, or helping biotech workers control pH levels. I once watched a wastewater plant operator reach for it to balance the acidity of sludge—without the water molecules clinging on, the powder wouldn’t dissolve right, leaving the process half-finished. Food scientists have their own stories, using it to stop magnesium shortfalls or balance tartness in tricky recipes. The hydrated formula provides a predictable magnesium release, which helps with dosing accuracy and consistent results.

Quality Checks and Authenticity

Quality control folks rely on exact formulas to set purity benchmarks. Counterfeit or poorly labeled chemicals can create headaches that reach far beyond science. In places where regulations fall short or supply chains get messy, products sometimes arrive mis-labeled or with the wrong hydration state. One manufacturer I visited took testing seriously, running molecular checks on every lot. They caught a bad batch before it ever reached classrooms—all thanks to a vigilant look at the formula and proper storage practices, since improper sealing can dry out or overhydrate the product.

Addressing Real-World Challenges

Mislabeling keeps showing up as a root cause when things go wrong, whether it’s lab mistakes, product recalls, or delays in production. Better education and supplier transparency protect everyone down the line. Storage also plays its part; moisture can change the compound, so using airtight containers and keeping an eye on expiration dates stops the formula from drifting. In government, more robust standards help—traceability lets labs and food producers spot inconsistencies early, saving time and resources.

The Power Behind the Formula

Knowing the chemical formula of magnesium acetate tetrahydrate, Mg(CH3COO)2·4H2O, does more than fill an exam blank. It ensures science, manufacturing, and healthy living run smoother. By paying attention to each part of the formula—magnesium, acetate, water—everybody from students to engineers works with confidence. Even outside the lab, this care with detail radiates outward, shaping safer outcomes and honest business.

Why Care About Storage?

Magnesium acetate tetrahydrate has a big role in labs and industry, but anyone who works with chemicals knows it’s not just about following the rulebook. A little careless mistake can ruin entire batches, hurt people, or waste money. I’ve seen labs lose whole supplies because humidity crept into containers or someone shrugged off a warning label. Those extra minutes spent storing things right save hours in cleanups and replacements. Magnesium acetate tetrahydrate deserves the same watchful approach.

Keeping It Dry

This compound clings to water in the air. Lid off for too long, and it starts to cake up or even liquefy. Humidity eats away at purity, so keep it tightly sealed in air-tight containers right after each use. Don’t trust zip bags or basic plastic tubs. Use glass, HDPE plastic, or steel containers with strong seals. I prefer desiccators, especially if your region sweats in summer. Tossing a few silica packs in each storage box doesn’t hurt either.

Cooler Temperatures Matter

Heat isn’t just a long-term threat. Warmth ramps up decomposition. Years ago I saw a university stockroom store their magnesium acetate close to a boiler—ruined after a month. Aim for a storage area that matches a standard office or home fridge. Under 25°C works well. Some suppliers push 15°C. Wherever possible, use the lower end of the range, especially in climates that swing wildly.

Shelter It from the Light

Quality takes a hit under sunlight. UV can kick off slow changes in the chemical makeup. Not as dramatic as with photosensitive drugs, but changes still creep in. Store in a dark cupboard or use amber glass containers. I’ve tried covering shelves with heavy cloth, but dedicated cabinets work much better.

Keep It Away from Reactive Chemicals

One careless shelf arrangement can lead to major messes—particularly if acids or oxidizers spill or give off fumes. Magnesium acetate tetrahydrate doesn’t always react violently, but it can degrade and lose potency. Stick with a chemical cabinet policy: all organics and volatile chemicals get separation, never sharing shelves with anything hygroscopic or easily altered by acid fumes.

Label Everything

Hard-to-read handwriting or missing dates trip up even experienced staff. Use clear, printed labels with chemical name, concentration, purchase date, and hazard symbols. Routine checks—once a month—help catch early signs of clumping or discoloration. I’ve built a habit of jotting down inspection notes. One time I caught half a dozen failing bottles before anyone started a new analysis.

Handling Spills and Waste

Magnesium acetate tetrahydrate isn’t as nasty as caustic soda, but don’t sweep it under the rug. I’ve seen eco rules tighten every few years. Scoop up spills with gloves, toss them in dedicated chemical waste bins, and avoid pouring anything down the drain. Treat all wipes and brooms used with the same care—no shortcuts here.

Simple Steps for Longevity

Foolproof storage comes down to a handful of habits: strong seals, dry air, darkness, cool spots, and away from threats. Smart labeling and staying alert with monthly checks wrap it all together. Small changes save budget headaches and lab time, while keeping people safe and science accurate.

Understanding the Substance

Magnesium acetate tetrahydrate pops up in everything from labs to food to environmental controls. Its place on chemical lists tends to make people nervous. I remember the first time I saw its long scientific name in an ingredients list — that jumble of syllables gave me pause. Some assume risk based solely on anything sounding complex. That’s not always fair.

Checking Recognized Hazards

Scientific sources, including material safety data sheets and peer-reviewed toxicology reports, don’t spotlight magnesium acetate tetrahydrate as a major toxic or hazardous chemical. The US Occupational Safety and Health Administration (OSHA) and the European Chemicals Agency don’t class it among dangerous substances you’d meet in a workplace or at home.

Accidental intake of small amounts rarely leads to severe consequences. I’ve talked to colleagues in food science labs who measure out grams at a time. Some had minor skin irritation or mild stomach discomfort when they handled large amounts without gloves or ate a poorly rinsed test batch. That’s rare and doesn’t match the “toxic” label some folks throw around.

Where Real Caution Comes In

Magnesium acetate tetrahydrate, like a lot of chalky powders in a chemistry closet, poses practical concerns if you ignore basic safety rules. It irritates eyes and skin for sure if you rub it in or breathe in a cloud of dust. Inhaling bigger amounts could make you cough or feel short of breath, especially if you’ve got asthma. No evidence points toward cancer risk, birth defects, or catastrophic poisoning under usual conditions.

The lethal dose stands impressively high, meaning you’d need to eat a huge amount for any dangerous effect. Compare that to table salt or household cough syrup—they actually pose more risk if someone takes too much. The acetate part ends up as vinegar inside the body, and the magnesium passes through urine. The risk shifts if someone has existing kidney trouble, as too much magnesium strains kidneys that aren’t filtering well.

Environmental Factors

Rinsed down a drain in reasonable amounts, magnesium acetate tetrahydrate doesn’t pile up in waterways or soil. It breaks down quickly, used by bacteria or dissolved into simple minerals. I checked with an environmental chemist who works on wastewater—she saw bigger issues from phosphates and plastics than from this salt. Fish or plants won’t suffer unless you unleash a truckload at once, which a typical user simply doesn’t do.

Ways to Handle It Safely

Sticking with gloves and goggles in labs makes sense. Keep powders off your food and don’t let unruly kids mess with open containers. Ventilate work areas or use a dust mask if there’s lots of powder in the air. If a spill happens, sweep up with a damp cloth—don’t blast the powder into a cloud. These simple steps drop the risk close to zero.

Education shapes a lot of healthy respect for chemicals. Clear instructions and common sense—protective gear, careful labeling, and not eating in work areas—matter more than rare warnings read off a data sheet.

Looking at the Bigger Picture

Magnesium acetate tetrahydrate is not a monster in the chemical cabinet. Experience in teaching labs, environmental work, and industrial settings shows far greater dangers from household cleaners or car exhaust than from this mild salt. Managing it responsibly and using plain good practices protects people, workplaces, and communities. Knowledge and care go a lot further than unfounded worry.

What Purity Means in the Real World

Every time I talk about chemicals like Magnesium Acetate Tetrahydrate, I remember back in college chemistry lab when I picked the wrong purity for a project and ended up redoing the whole thing. Purity isn’t just a number on a label—it's the backbone of why some experiments succeed and others flop. The most common grades you'll run into are technical, laboratory, and analytical—each with its own standards and each designed to make or break specific work.

What Are “Technical” and “Laboratory” Grades?

Technical grade feels sort of like the workhorse of the lot. It fits situations where a few impurities don't throw off the results—so folks in large-scale manufacturing or wastewater treatment like it because the processes there leave wiggle room for error. Purity around 98% to 99% doesn't bother them much, especially when mixing chemicals or treating environmental waste.

On the other side, laboratory grade steps the quality up for classrooms or basic research, running above 99%. That level won't make a difference in industrial settings, but for classroom experiments or quality control labs, I’ve seen just how much it removes variables that can turn decent work into guesswork.

The Quest for Analytical Grade

Analytical Reagent grade, usually labeled AR or ACS, speaks most to anyone who’s had to defend their data in a scientific journal or production audit. Purity hits 99% plus, and every contaminant gets documented down to the fractions of a percent. I remember my nerves every time I had to sign off on a certificate of analysis at a food testing lab; with raw data that exact, there’s no room to fudge results. This grade keeps labs, pharmaceutical companies, and food safety outfits in the clear, both legally and scientifically.

Why Grades Actually Matter

Companies and researchers end up sinking resources into the wrong grade and then discover hidden costs. Technical grade looks cheap upfront, but chemical residues can gum up machines or taint final products, and those cleanup bills or product recalls aren’t cheap. Choosing analytical grade for routine jobs, on the other hand, drains budgets fast. So, matching the job to the grade saves headaches. In research, even a trace contaminant from a low-grade supply could trigger false positives or spoiled cultures—seen that first-hand, and it’s a hard lesson.

A lot of buyers also don’t realize how storage affects purity, as magnesium acetate tetrahydrate loses quality if it sits too long or soaks up moisture. I’ve watched it clump and lose accuracy in measurements more times than I care to count. Perform checks on age and storage conditions, not just on paperwork.

Finding the Right Grade, Avoiding Trouble

Too often, folks skip the step of reviewing supplier certifications. I always ask for up-to-date batch analysis and find out if they're ISO certified—total peace of mind over unreliable supply chains. Purity and grade determine project costs, lab safety, and regulatory compliance. Buying a few cents cheaper per kilogram sometimes leads to costly rework if the grade doesn’t fit the need.

If you’ve got doubts, reach out to a chemical safety officer or a trusted vendor. I’ve saved money and projects just by making that extra call before hitting “order.” Purity matters much more than people realize until the mistake is in the test tube or on the assembly line.

| Names | |

| Preferred IUPAC name | magnesium diacetate tetrahydrate |

| Other names |

Acetic acid magnesium salt tetrahydrate

Magnesium ethanoate tetrahydrate Magnesium(II) acetate tetrahydrate |

| Pronunciation | /mæɡˈniːziəm əˈsiːteɪt tɛtrəˈhaɪdreɪt/ |

| Identifiers | |

| CAS Number | 16674-78-5 |

| Beilstein Reference | 3924041 |

| ChEBI | CHEBI:63068 |

| ChEMBL | CHEMBL1201646 |

| ChemSpider | 156531 |

| DrugBank | DB14506 |

| ECHA InfoCard | 20b2d6d2-28e8-4626-8aa7-f3f48e1f7a6e |

| EC Number | 204-540-6 |

| Gmelin Reference | 15587 |

| KEGG | C14834 |

| MeSH | D008263 |

| PubChem CID | 129701 |

| RTECS number | OM3675000 |

| UNII | DW3Q939A49 |

| UN number | UN2813 |

| Properties | |

| Chemical formula | Mg(C₂H₃O₂)₂·4H₂O |

| Molar mass | 214.49 g/mol |

| Appearance | White crystalline powder or granules |

| Odor | Odorless |

| Density | 1.45 g/cm³ |

| Solubility in water | Very soluble |

| log P | -2.6 |

| Acidity (pKa) | 8.5 |

| Basicity (pKb) | 9.0 (for acetate ion) |

| Magnetic susceptibility (χ) | −23.0×10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.422 |

| Viscosity | Viscous liquid |

| Dipole moment | 2.56 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 234.5 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | –1860.85 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -1534 kJ/mol |

| Pharmacology | |

| ATC code | A12CC04 |

| Hazards | |

| GHS labelling | GHS07, GHS08 |

| Pictograms | GHS07 |

| Signal word | Warning |

| Hazard statements | May cause respiratory irritation. |

| Precautionary statements | P264, P270, P280, P301+P312, P330, P501 |

| Autoignition temperature | 350 °C (662 °F) |

| Lethal dose or concentration | LD50 Oral Rat 810 mg/kg |

| LD50 (median dose) | LD50 (median dose): Oral, rat: 8100 mg/kg |

| NIOSH | MI1100000 |

| IDLH (Immediate danger) | No IDLH established |

| Related compounds | |

| Related compounds |

Magnesium acetate

Magnesium carbonate Magnesium chloride Magnesium sulfate Calcium acetate Zinc acetate |