Ethyl Acetate: From Discovery to Industry Staple

Historical Development

Ethyl acetate’s story stretches back almost two centuries. Scientists first identified it in the early 1800s as chemists dug into the curious intersection of organic acids and alcohols. The French chemist, Antoine Balard, contributed to this path, watching reagents fizz and combine as part of Europe’s race to chart new molecules after the Industrial Revolution. Early on, folks harnessed labor-intensive distillation, blending vinegar-derived acetic acid with common ethanol. Lab stories from this period share a sense of hands-on risk, whether from open flames or little understanding of volatile vapors. Laboratory glassware evolved alongside these experiments. By the late 19th century, chemical engineers streamlined processes, letting industry scale up. This created cheaper solvents for manufacturing, leather tanning, perfumery, and even early film stock. Folks working in these plants carried forward lessons learned: mask up, ventilate your spaces, respect the unpredictable. That past matters today—manufacturing hasn’t forgotten those early headaches and breakthroughs.

Product Overview

Ethyl acetate shows up in all sorts of places in daily life. Its strong, fruity smell brings to mind model glue, nail polish, and some wines. Companies ship it as a clear, colorless liquid that quickly evaporates if left open. With solid roots in the solvents market, it smooths out paint, keeps pharmaceutical factories humming, and lends itself to aroma chemistry—artificial flavors and fragrances bank on it. Every bottle carries a chemical simplicity, yet what sits inside is the product of over a century of growing technical knowledge. Inventory rolls into warehouses with a specific gravity just above 0.89 at room temperature, packed tight to discourage leaks. Production outfits focus on keeping purity above 99.5% for most uses, making it a favorite for extraction and chromatography work in research settings. For manufacturers, the cost, odor, and volatility make it a no-brainer, given the jobs it does compared to pricier, slower-drying alternatives.

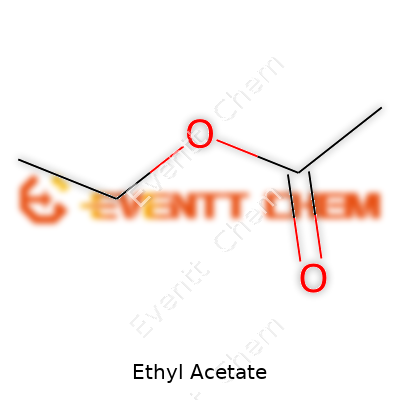

Physical & Chemical Properties

Open a bottle of ethyl acetate and its volatility greets you right away. Its boiling point sits at around 77°C, and it hits the freezing point at -83.6°C. Folks working in quality control labs often check refractive index, which hangs near 1.372 at 20°C. The vapor pressure, high even at room temp, means it demands careful storage; nobody wants evaporative losses or headaches from a room left unventilated. Ethyl acetate floats slightly above water if poured together but separates quickly, since it doesn’t mix in high concentrations. Flammable to the core, with a flash point below 4°C, it needs solid fire safety. Chemically, the molecule carries the functional group of an ester (CH3COOC2H5). That structure gives it both a sweet smell and its power to dissolve a huge range of organic materials: resins, lacquers, gum, oils. Finding ways to blend safety with usefulness keeps plant managers and scientists both busy and sometimes anxious.

Technical Specifications & Labeling

Regulation tightened over the years. Labels on ethyl acetate containers carry standard hazard diamonds—red for flammability dominates, blue for health warnings, yellow to show it can react with strong oxidizers. Factory supply chains require documentation outlining specific gravity, amount in kilograms or liters, test results confirming limits on water and impurities, and expiration dates tied to storage conditions. Suppliers also certify shelf-life based on bottling, not just purity grade. Every drum gets tracked with a UN number (1173 for ethyl acetate), supported by transport guidelines from road to sea freight. Details show that small impurities, like ethanol residues or water, steer certain applications off-course. For chromatographers or those extracting delicate flavors, the tiniest contamination ruins results. Safety Data Sheets (SDS) include all the warnings: keep cool, avoid sparks, use only in well-ventilated spaces, and wear suitable gloves and goggles. Each of these evolved after decades of accident reports and changing standards.

Preparation Method

Factories today rely on large-scale chemical synthesis, opting mostly for the Fischer esterification method. This brings together acetic acid with ethanol in the presence of strong acid—usually sulfuric acid—as a catalyst. The setup recycles unreacted starting materials using distillation columns, since cost efficiency counts as much as yield. Some older routes used the Tischenko process, where acetaldehyde plays a starring role, especially in regions flush with cheap feedstock. Constant tweaking of pressure, temperature, and recycle loops pushes companies closer to near-total conversions. Smaller labs or specialty suppliers still lean on batch processes, carefully managing heat and stirring to avoid runaway reactions or uneven mixtures. What draws my respect is the way each plant must juggle waste streams: handling acidic by-products, recovering excess solvents, and cleaning catalyst residues all add to the challenge. Down in research settings, green chemistry methods—catalysis, recyclable reagents—have entered the conversation, especially as folks work to reduce emissions and improve efficiency.

Chemical Reactions & Modifications

Ethyl acetate serves as both product and starting point for other reactions, making it a true workhorse. Hydrolysis drops it into acetic acid and ethanol, reversed from typical synthesis—this becomes important in the chemical recycling of esters. Chemists use strong bases in the classic saponification reaction to draw out carboxylate salts, which build up polymers and specialty surfactants. Its mellow reactivity allows for transesterification, where other alcohols step in to swap one end of its molecule, letting researchers fine-tune physical qualities for lubricants or flavor compounds. It often acts as a solvent for Grignard and Friedel-Crafts reactions, where keeping things anhydrous and avoiding side reactions tests the mettle of even experienced bench chemists. In my own projects, chasing high yield from a reaction often meant balancing its solvent effects—its fast evaporation sometimes forced me to adjust my technique for capturing final products cleanly.

Synonyms & Product Names

Ask for ethyl acetate in the shop and you might catch a sideways glance if someone prefers trade names. Folks also know it as “ethyl ethanoate”, “acetic ether”, or “EA”. Some product catalogs list it as “acetic acid ethyl ester” or “ethyl ester of acetic acid.” In the fragrance world, import sheets sometimes call it “Essigäther,” a nod to old German chemical nomenclature. Over the years, large chemical suppliers have stamped their own brand or shorthand—my personal memory recalls confusion unpacking shipments, as labels toggled between “EA,” “EtOAc,” and the full name, depending on country of origin or regulatory code. All these aliases matter; missing a single one could mean delayed shipments or mix-ups in paperwork that stalls production, especially for smaller outfits managing complex international orders.

Safety & Operational Standards

Every chemist I know has a story that foregrounds the hazards of ethyl acetate. In workplaces, it demands robust ventilation, spark-proof fans, and careful use of personal protective equipment. Companies enforce storage away from direct heat, ignition sources, and oxidizing chemicals. Flammable storage cabinets get regular checks for drum and container leaks. Some plants monitor air for vapor concentrations, especially where spills have happened before. Occupational health standards draw on both OSHA and European Union rules, with threshold limits for airborne concentrations around 400 ppm over an eight-hour work day. Workers receive ongoing training, with drills for spill response: sand, upgraded absorbent materials, and clear evacuation routes. Fires fueled by this chemical race up fast—fire marshals often point to historical accidents to justify strict local codes. In handling waste, facilities employ grounding and bonding on drums, since static discharge can mean disaster. I remember a peer recounting a minor static spark that reminded everyone not to cut corners on grounding; lessons like these stick because the risks remain very tangible.

Application Area

It’s tough to find a corner of modern life untouched by ethyl acetate. Factories use it as a solvent to combine pigments in paint, or as a carrier in printing inks and adhesives. In pharmaceuticals, it extracts active ingredients, purifies compounds, and cleans reaction vessels. Perfume manufacturers rely on its volatility for quick-drying fragrances, supporting both affordable daily scents and luxury blends. The food industry uses trace amounts to add a signature fruitiness to candies, baked goods, wine, and spirits, though strict purity guidelines shape this usage. Laboratories across the globe lean on it during chromatography, where its polarity matches up well with separating out molecules on TLC plates or in liquid-liquid extractions. Even nail salons owe fast-drying polishes to ethyl acetate’s evaporation rate—small details, but it matters for businesses that serve hundreds daily. Each sector values its special set of physical traits, from solubility to aroma, giving rise to robust global trade.

Research & Development

Over recent decades, research on ethyl acetate has taken two clear tracks: improving sustainability and finding new specialty applications. Researchers tinker with bio-based production routes, such as fermentation from sugars using engineered yeasts or bacteria, seeing if nature’s efficiency can outpace traditional petrochemical routes. Pilot plants now produce small but growing volumes of “green EA,” aiming to reduce carbon footprints and dependence on fossil fuels. Academics publish findings on catalyst improvements, trying to bump up yields at lower temperatures to cut energy bills industry-wide. In application science, recent patents show ethyl acetate joining the suite of solvents for battery manufacture, electronics cleaning, and specialty coatings. Some hope its relatively benign health profile, compared to other solvents, opens new paths for safer industrial chemistries. From where I stand, the push from both ends—process improvement and final product innovation—keeps research humming in universities, private labs, and start-up corridors.

Toxicity Research

Despite broad use, ethyl acetate demonstrates low acute toxicity for most adults. Inhalation at high concentrations, though, produces classic symptoms—headache, dizziness, throat irritation. Chronic exposure brings different risks, from skin dryness to possible nervous system effects, though these remain rare outside heavy industry. Most toxicology studies agree that it gets processed quickly in the liver, breaking down into harmless acetic acid and ethanol. Animal studies indicate only mild respiratory irritation and little in the way of carcinogenic potential or reproductive toxicity. Still, vigilance around worker safety grows; newer studies check for subtler impacts, such as cumulative effects from working around various solvents at once. Regulatory agencies update permissible exposure levels based on new data, aiming to balance worker health with economic realities in manufacturing. In my experience, safety committees watch not just individual figures, but real-world conditions—ventilation, breaks, protective gear—all of which shape actual exposures far more than lab values alone ever could.

Future Prospects

The demand for ethyl acetate keeps climbing as emerging markets ramp up manufacturing, coatings, and pharmaceuticals. Sustainability hangs over the next chapter—upcoming regulations steer companies away from wasteful or high-emission production methods. Startups and legacy producers both chase eco-friendly processes, like renewable feedstocks or closed-loop recovery systems. Green chemistry advocates look to minimize by-products, shrink energy demand, and bolster safety at all steps. In high-tech fields, researchers consider ethyl acetate as part of next-generation battery and recyclable plastics manufacturing, carving out new roles beyond the traditional paints and adhesives. Digitalization—automation, smart monitoring—promises safer operational control, catching leaks before they start trouble. Looking ahead, I see the core challenge as walking the tightrope between economic survival and greener, safer production. This journey runs on the expertise, caution, and willingness to adapt that has always marked the chemical industry’s best contributors.

A Simple Solvent With Big Impact

Ethyl acetate isn’t a chemical most folks talk about over dinner. Yet it shows up again and again in our daily lives, often without much recognition. Its fruity smell gives nail polish remover that sharp kick. That same scent drifts out of fresh paint or glue in the garage. I remember storing a half-full can of paint thinner in my shed and realizing how quickly it could clear a stubborn spot of sticky residue. That was ethyl acetate at work.

Hiding in Plain Sight — From Perfume to Decaf Coffee

Open any bottle of perfume and you’re likely getting a whiff of ethyl acetate. Perfumers use it to dissolve and carry sweet or sharp notes. It evaporates fast, leaving behind only the fragrance itself. For folks looking to enjoy a cup of decaf, the beans often go through a gentle wash of ethyl acetate to pull out the caffeine. The process became known as "natural decaffeination" when chemists realized fruits like apples and bananas create ethyl acetate on their own.

Helping Clean and Mend

Walk through a print shop or an automotive body shop and the sharp smell signals ethyl acetate at play. Print shops depend on it for its fast evaporation—ink dries smooth on magazines and packaging. Mechanics reach for cleaners and degreasers with ethyl acetate when removing gunk from engine parts. Shoe repair shops often brush it on before gluing soles, speeding up repair jobs that used to take all day.

Safety Concerns Worth Noting

Chemists and factory workers have long worried about the risk of inhaling too much ethyl acetate. Short exposure can lead to headaches or a scratching throat. Some workers, after years on the job, have mild asthma. The National Institute for Occupational Safety and Health lists guidelines and limits, but I once watched a painter pull his mask up only after coughing—personal habits make a real difference, not just safety sheets. Homeowners and hobbyists often don’t realize how quick the fumes gather in small rooms. Ventilating a space, working outside, or wearing a mask protect against nausea or dizziness.

The Bigger Picture: Greener Alternatives

Chemical spills and air pollution link back to solvents such as ethyl acetate. Large factories often release it into the air, and small businesses may dump excess without thinking. I’ve seen local art teachers trying citrus-based cleaners in place of harsher solvents. Paint companies now experiment with water-based solutions, especially for schools and homes where safety matters most. National agencies encourage industries to keep emissions low. Simple steps—like storing containers tightly closed—make a dent in reducing chemical vapors.

Making Informed Choices

If you want to avoid unnecessary exposure, scan product labels for common solvents. Household products list ingredients more clearly now as consumer groups push for transparency. Parents can guide kids toward water-based paints and glues. Workers should learn best practices—using fans, sealing off containers, and wearing proper gloves or masks.

Ethyl acetate finds its way into a surprising number of places. Understanding its uses, risks, and greener alternatives can lead to healthier homes and workplaces. Making even small changes adds up over time.

Everyday Encounters and Facts

Ethyl acetate pops up in many corners of daily life. Nail polish remover, paint thinner, and even some decaf coffees rely on this clear, sweet-smelling liquid. Industrial workers and science students often get familiar with its sharp scent early on. It evaporates quickly, doesn’t hang around in the air for long, and won’t leave tacky residue. These traits make it popular for quick-dry products or jobs needing fast cleanup.

Thinking About Safety

Many people feel uneasy about chemicals with names they can’t pronounce. Ethyl acetate sounds intimidating until one learns it comes from ethanol (the drinking alcohol) and acetic acid (the punch in vinegar). Safety, though, has less to do with where a chemical comes from and more with how it’s handled. Pure water can drown; salt can poison in high enough doses. So the real question is: does normal use carry much risk?

Research from the U.S. Environmental Protection Agency (EPA) and the European Chemicals Agency lists ethyl acetate as a substance with low acute toxicity. The U.S. Food and Drug Administration even allows its use as a flavoring agent in foods (in tiny doses). Science journals say ethyl acetate breaks down quickly in the air, doesn’t linger in soil or water, and isn’t considered hazardous waste under everyday commercial use.

That said, the sharp, fruity odor actually warns that too much at once can bother the nose, throat, or eyes. Extended, heavy-duty exposure can lead to headaches or mild dizziness. For years, working in a busy print shop brought me face-to-face with chemicals like this. When the fan stopped working or venting got ignored, everyone noticed—the aches and irritation told us right away. Over time, jobs that skipped gloves or masks led to dry skin and coughing.

Common Sense Rules

Science and government agencies give solid advice. Use ethyl acetate in a spot with good airflow—a kitchen counter won’t cut it for major paint jobs. Keep lids tight and bottles away from kids or pets. Rubber or nitrile gloves prevent dry or cracked skin, and splash goggles stop eye trouble. If the job keeps you in contact for hours, a proper respirator matters much more than a simple dust mask.

One thing to watch for: open flames. Ethyl acetate lights up fast, making it a hazard near candles, stovetops, or even electrical sparks. It’s smart to treat it like gasoline and store it in the same kind of cool, well-marked spot. If a spill happens, soaking it up with absorbent material and getting rid of rags as fire waste avoids trouble later.

What Really Matters

The world runs on substances that have both pros and cons. With practical care, ethyl acetate does its job safely for millions of people every day. If you’re curious, most safety data sheets are free online—a priceless resource before starting any big project. My own rule for any unsteady chemical: trust your nose and skin. When something feels off, better safe than sorry.

Workspaces evolve, not everyone reads every label, and mistakes happen. But good habits—cracking a window, closing the cap, wearing gloves—turn risk into just another part of the job, not a constant worry.

Getting to Know Ethyl Acetate

Ethyl acetate isn’t something you’ll find in most people’s kitchen cabinets, but anyone who’s worked in a lab or painted a room probably knows its sweet, fruity smell. Used everywhere from nail polish removers to decaffeinating coffee, this solvent has a set of physical traits that make it both useful and, sometimes, a little tricky to handle.

It’s a Liquid—But Not for Long

If you open a bottle of ethyl acetate, it won’t stick around for a chat. With a boiling point around 77°C (171°F), the liquid quickly gives way to vapor. You’d notice this even at room temperature, since the stuff evaporates with surprising speed. Back in chemistry class, I’d lose almost half a beaker to the air within minutes if I wasn’t careful. The rapid evaporation means you should always work in well-ventilated spaces.

Light as a Feather, Compared to Water

You might expect something liquid to weigh about the same as water, but ethyl acetate is lighter. Its density hovers near 0.9 g/cm³ at room temperature, so it actually floats on water. I learned this the hard way once, thinking I could mix it straight into an aqueous solution. Since it forms a layer on top, combining it with water takes effort unless you shake or stir vigorously.

Clean, Clear… and a Bit Flammable

I can’t forget those safety posters in college, warning about flammable chemicals. Ethyl acetate fits right in. It’s a colorless, transparent liquid, but its flash point—just above -4°C (25°F)—means a stray spark could get things heated in the worst way. Storage away from heat sources isn’t just a suggestion; it’s a necessity. One jolt of static electricity, and the risk of fire jumps dramatically.

That Famous Smell

People recognize the smell first. Even low concentrations in the air give off a scent that reminds me of pears or certain cleaning fluids. Its vapor pressure at 20°C is about 73 mmHg, so it doesn’t take much for a room to fill with its aroma. Occupational health guidelines aren’t just arbitrary. Prolonged inhalation can irritate eyes and lungs, and the low boiling point only increases exposure risk.

Mixing and Solving Problems

What helps ethyl acetate excel as a solvent is its miscibility with lots of organic liquids—alcohols, esters, even acetone. It doesn’t mix well with water, making it useful for separating chemicals by extraction. This property helps manufacturers remove caffeine from coffee and tea in a selective, efficient way. The same feature draws artists and scientists, since few other solvents clean up oil-based paints or dissolve adhesives so quickly.

Handling with Respect

Spills are simple to manage on small scales. With its quick evaporation, minor spills leave practically no residue. Still, there’s more to think about: repeated skin contact dries out skin, sometimes leading to irritation. I keep gloves handy whenever I handle it, even for quick jobs. Because it collects in closed spaces, good ventilation stops both headaches and potential disasters.

The Responsible Choice

Ethyl acetate makes modern life easier, from fragrance manufacturing to cleaning electronics. Its physical properties give it that usefulness, and each trait brings both benefits and potential downsides. Respect in handling, good ventilation, and keeping away from flames go a long way in making sure it stays a helpful tool, not a hazard.

The Constant Challenge of Flammable Liquids

Ethyl acetate never fails to show up in labs and factories. Its sweet, fruity smell hangs in the air wherever paints, adhesives, or pharmaceuticals exist. The stuff works as a decent solvent, but it also packs a punch as a flammable liquid. I’ve watched even seasoned workers show a casual approach to handling ethyl acetate, but I learned the hard way how a little oversight can leave lasting lessons.

A Real Look at Containment

Metal or high-density polyethylene drums outlast flimsy containers by a mile. A beat-up lid, a rusty seam, or a wrong plastic type spells trouble. Ethyl acetate vapor loves leaking and finds the tiniest hole. Once fumes escape, they creep along surfaces, looking for a spark or flame to latch onto. My experience tells me to always check gaskets, keep all caps snug, and ditch any container that looks questionable.

Ventilation: The Unsung Hero

No substitute exists for fresh air. Poorly ventilated rooms trap vapor, and concentrations climb faster than folks realize. At one shop, an old storeroom doubled as a catch-all for chemical leftovers. Keeping ethyl acetate there turned the place into a time bomb. Fans, open windows, and working HVAC systems clear the air. Outdoor storage protects best, but that isn’t always possible. Even so, keeping the interior breezy can save lives.

Temperature and Fire Safety

Hot rooms speed up evaporation. It doesn’t take much sunlight or a steamy boiler room to turn storage tanks into hazards. I always kept cans away from radiators or windows. Flameproof cabinets shine here. Most come with self-closing doors and thick walls. Sprinkler heads right above a storage shelf seem like an afterthought, but fire codes require them for good reason. They buy precious minutes if disaster strikes.

What Labels Really Mean

Some folks ignore labels once the container’s been around awhile. Outdated or hand-written labels invite mistakes. Swapping labels or using illegible tags once led to a major cleanup in my workplace. Printed, chemical-resistant labels solve confusion and save time. Safety Data Sheets stuck close by offer fast answers in a pinch.

Personal Safety and Training

Gloves, goggles, and a splash apron give a fighting chance against spills. Lost count of how many times gloves protected against chemical burns. Emergency showers and eye wash stations shouldn’t gather dust. I witnessed a co-worker splash his forearms and race to a station. The safety drill from the month before kicked in, and his quick actions made all the difference.

Investing in Safety Pays Off

Some managers treat storage guidelines as a box-ticking exercise. That approach courts both disaster and cost. Small steps—replacing seals, routine checks, yearly safety refreshers—build a culture where emergencies stay rare. Insurance premiums shrink, downtime disappears, and everyone goes home in one piece.

Better Storage Reduces Waste

Fresh ethyl acetate keeps its edge far longer in the right conditions. Exposure to light, moisture, or air turns it stale. My teams always rotate stock and mark “first in, first out” on new drums. Waste haulers don’t come cheap, so keeping surplus solvent fit for reuse cuts bills and headaches.

Why This Matters

Safe storage means more than checking off compliance. It’s about protecting people, property, and the business’s reputation. Each small habit, from proper labels to airflow checks, reduces risk. Experience proves it doesn’t take a huge investment—just consistency and respect for what ethyl acetate can do.

Why Ethyl Acetate Demands Respect

Ethyl acetate pops up in more places than most people expect. It turns up in nail polish remover, lab work, even in some cleaning products. The thing is, just because it’s common doesn’t mean it’s harmless. Its strong, sweet smell might trick some into thinking it’s safer than it is, but there’s no shortcut. Having worked around it in my own time in research settings, I’ve seen plenty of folks get caught off-guard by spills or headaches from fumes. Simple knowledge—mixed with respect—keeps everybody out of trouble.

Good Ventilation Beats Regret

Ethyl acetate evaporates fast, and that vapor doesn’t do anybody favors. That sticky-sweet odor signals the presence of vapors that can irritate nasal passages and the lungs. One time a coworker closed a window to keep out the cold. Twenty minutes later, we all felt lightheaded. Lesson learned: fresh air matters more than comfort. So whether you’re using it for work or hobbies, crack those windows and use exhaust fans. Fume hoods aren’t just for show in labs—they make a world of difference.

Personal Protection: Non-Negotiable

Too many people skip gloves or goggles in a rush. I recall my own forgetfulness back in college, splashing some ethyl acetate on my arm. It burned for hours. This isn’t scare talk—it’s chemistry 101. Nitrile gloves, chemical splash goggles, and a solid lab coat or apron take minutes to put on but block most common routes for exposure. Safety data from chemical manufacturers and OSHA both point out direct skin or eye contact brings real risk, including burns or longer-term health issues.

Avoid Ignition Sources, Always

This liquid lights up almost as easily as gasoline. Smoking indoors, friction sparks, or just plugging in equipment—if ethyl acetate is nearby, even a tiny open flame or spark can turn a routine task into an emergency. I’ve seen fire drills go real in seconds during a spill in a poorly ventilated lab. Store the solvent in flame-proof cabinets, and keep containers tightly sealed. Make sure fire extinguishers rated for chemical fires remain within reach.

Smart Storage and Clean-Up Habits

Storing ethyl acetate takes more than just screwing the cap back on. Use HDPE or glass containers, and keep them out of sunlight and heat. Proper labeling matters—so everyone knows what’s inside, even months later. For spills, act fast: absorb with sand or a spill pad, ventilate the area, and dispose of waste using local hazardous materials protocols. Playing fast and loose with cleanup invites trouble downstream, including fire risk and toxic exposure.

Trust the Facts—And Each Other

The U.S. Environmental Protection Agency and National Fire Protection Association both warn against mishandling this solvent. Companies and schools must lean into training, not just paperwork. In my own experience, quick conversations about safety right before a task boost confidence and lower risk. Peer checks, refresher trainings, and easy access to safety data sheets keep teams healthy and accidents rare.

Better Solutions Build Real Safety Culture

Finding safer substitutes takes effort, but it pays off. Teams can explore less volatile options or use automation in industrial settings to shrink exposure time. If it must be ethyl acetate, use only as much as absolutely needed and keep open communication. It’s not enough to just know the rules—real safety grows when people feel free to speak up and watch out for one another.

| Names | |

| Preferred IUPAC name | Ethyl ethanoate |

| Other names |

Acetic acid ethyl ester

Ethyl ethanoate Acetic ester |

| Pronunciation | /ˈiːθɪl ˈæsɪteɪt/ |

| Identifiers | |

| CAS Number | 141-78-6 |

| Beilstein Reference | 635923 |

| ChEBI | CHEBI:27750 |

| ChEMBL | CHEMBL44537 |

| ChemSpider | 5378 |

| DrugBank | DB03157 |

| ECHA InfoCard | 03b0eafe-41bd-4e31-8250-e19950e3f4fd |

| EC Number | 205-500-4 |

| Gmelin Reference | 604 |

| KEGG | C00989 |

| MeSH | D005002 |

| PubChem CID | 8857 |

| RTECS number | AH3325000 |

| UNII | UMB835ZL9M |

| UN number | 1173 |

| Properties | |

| Chemical formula | C4H8O2 |

| Molar mass | 88.11 g/mol |

| Appearance | Colorless transparent liquid |

| Odor | fruity |

| Density | 0.897 g/cm³ |

| Solubility in water | 8.3 g/100 mL (20 °C) |

| log P | 0.73 |

| Vapor pressure | 73 mmHg (20°C) |

| Acidity (pKa) | 25 |

| Basicity (pKb) | pKb = 15.5 |

| Magnetic susceptibility (χ) | -42.2×10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.370 |

| Viscosity | 0.45 mPa·s |

| Dipole moment | 1.78 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 160.7 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -483.7 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -2220 kJ/mol |

| Pharmacology | |

| ATC code | D01AE23 |

| Hazards | |

| GHS labelling | **GHS02, GHS07** |

| Pictograms | GHS02, GHS07 |

| Signal word | Warning |

| Hazard statements | H225, H319, H336 |

| Precautionary statements | P210, P233, P240, P241, P242, P243, P264, P280, P303+P361+P353, P305+P351+P338, P337+P313, P370+P378, P403+P235, P501 |

| NFPA 704 (fire diamond) | 2-3-0 |

| Flash point | -4°C (25°F) |

| Autoignition temperature | 427 °C |

| Explosive limits | 2.1% - 11.5% |

| Lethal dose or concentration | LD₅₀ oral (rat): 5,620 mg/kg |

| LD50 (median dose) | LD50 (median dose): 5,620 mg/kg (oral, rat) |

| NIOSH | **K088** |

| PEL (Permissible) | PEL: 400 ppm (1400 mg/m³) |

| REL (Recommended) | The REL (Recommended Exposure Limit) of Ethyl Acetate is: "400 ppm (1400 mg/m3) TWA |

| IDLH (Immediate danger) | 2000 ppm |

| Related compounds | |

| Related compounds |

Acetic acid

Ethanol Acetaldehyde Methyl acetate Butyl acetate Isopropyl acetate |