Cupric Acetate Monohydrate: Foundations, Properties, and Perspectives

Historical Development

Cupric acetate monohydrate has come a long road from its earliest appearance in the dyeing vats of the Middle Ages, when cloth-makers relied on copper salts for the deep blue-green shades prized across Eurasia. The substance held a reputation not just for coloring, but also as part of early chemical recipes for preservatives and pigments. In nineteenth-century laboratories, cupric acetate emerged as a portal for scientists probing the new field of transition metal chemistry, gaining a foothold in foundational coordination chemistry texts. By the early twentieth century, large-scale production in chemical plants unfolded, as industrial processes harnessed its crystalline structure for textile, agricultural, and laboratory uses. Today, the forks in development keep coming, shaped by demands from industry, agriculture, and academic research.

Product Overview

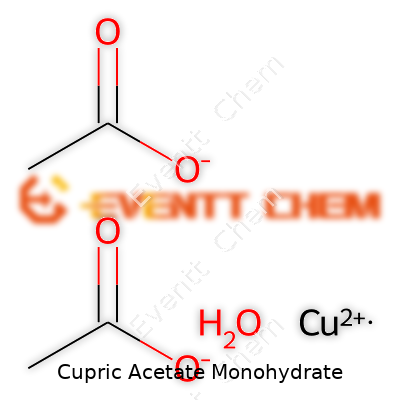

Cupric acetate monohydrate sits among copper(II) carboxylate salts, appearing as blue-green crystals and carrying the formula Cu(CH3COO)2·H2O. Its production roots trace back to copper’s readiness to swap electrons and take part in oxidation-reduction cycles. In the factory batch, the compound’s ease of handling, water solubility, and distinct color make it a mainstay among laboratory reagents, wood preservatives, catalysts, and fungicide ingredients. From my time in environmental chemistry, few reagents offer such reliability, blending straightforward preparation with visible reactions. This directness gives it an advantage: researchers and operators can identify contamination or degradation with the naked eye.

Physical & Chemical Properties

Cupric acetate monohydrate stands out with a blue-green, needlelike crystalline form. Its molar mass lands at about 199.65 g/mol with one water molecule locked to each copper atom. The melting point hovers around 115°C, at which it loses water of crystallization, and above 240°C, decomposition sets in, leaving copper(II) oxide and acetic acid vapors in its wake. Solubility in water is notable—about 7.2 grams dissolve in 100 ml of cold water, increasing as temperature rises—reflecting a readiness to participate in a wide array of chemical reactions. The crystals give off a mild acetic odor; in the humid summer weeks, you can sense it emerging from storage jars. Chemical properties show a classic divalent copper center bonded to acetate ligands, which can easily trade places with other ligands under the right conditions. In the presence of reducing agents, the blue-green fades to brownish tones as copper(I) or copper(0) forms, while oxidizing conditions restore those characteristic hues.

Technical Specifications & Labeling

Quality suppliers must ensure a minimum of 98% purity, with heavy metal contaminants—chiefly iron, lead, and arsenic—kept lower than 10 ppm to meet both industrial and research requirements. Labeling on certified containers details hazard statements (notably for toxicity to aquatic life and health risks if mishandled), recommended storage at temperatures between 15°C–30°C, and UN identification codes for international transport. Batch information includes manufacturing and expiration dates. These markings come with regulatory backing in markets like the United States and European Union, linking chemical safety data to strict inventory management. Anyone sourcing or handling the product directly recognizes much of the labeling—warnings in black and red, instructions for accidental spills, and reagent grade marks—reflecting years of accumulated knowledge about risks and best practice.

Preparation Method

Traditional synthesis starts with the controlled reaction of copper(II) carbonate or copper(II) oxide with acetic acid, yielding the blue-green salt and water or carbon dioxide as byproducts. Modern operations scale this up through semi-continuous processes, feeding copper metal shavings and dilute acetic acid under moderate heating and aeration, which improves conversion by maintaining oxygen levels. The resulting solutions cool, and crystals form as water evaporates or as cold acetone “kicks out” the salt. Efficient filtration and vacuum drying follow. In university or high-school laboratory settings, small-batch preparation acts as a classic demonstration of double displacement and crystallization—the powders and solutions offering immediate feedback through shifting colors and crystal shapes.

Chemical Reactions & Modifications

Cupric acetate monohydrate’s two acetate groups offer gateways for a slew of reaction paths. They enable ligand exchange in basic or nucleophilic media, allowing for preparation of copper complexes with chelators like EDTA or ammonia. As a mild oxidant, it can convert alcohols to aldehydes, especially in the presence of added co-reactants. It catalyzes organic syntheses, including ring closure reactions and oxidative coupling, giving it a foothold in the production of specialty chemicals. The acetate can swap for other carboxylates, and in the presence of phosphines or thioethers, the structure bends and shifts into new coordination environments, painting a picture of the copper ion’s versatility. In undergraduate laboratories, the sight of a solution’s color shift—from deep blue to pale green or brown—signals reaction progress without the need for fancy instruments.

Synonyms & Product Names

The compound’s common aliases include copper(II) acetate monohydrate, cupric ethanoate monohydrate, and verdigris. On procurement orders or chemical registries, it might carry the names copper acetate, blue verdigris, or Cu(OAc)2·H2O. For regulatory and inventory purposes, its CAS number—6046-93-1—directs users straight to standardized data sheets. These synonyms sometimes trip up first-time buyers, especially those mixing up verdigris as a pigment with other copper salts found in paints and horticultural applications.

Safety & Operational Standards

Handlers face well-documented risks: direct exposure can irritate skin and eyes, while inhaling dust or fine particles may harm respiratory tissues. Prolonged or excessive contact even at modest concentrations will cause headaches, nausea, or organ stress, especially if ingested or inhaled over time. In the environment, runoff containing the compound stokes acute toxicity in aquatic organisms, a problem witnessed in poorly regulated agricultural sites. Strict operating standards—gloves, goggles, fume hoods, and secure storage—form the bedrock of safe use in every laboratory or warehouse. Spill procedures must be drilled regularly, as copper salts corrode metals and damage piping when left unchecked. Risk assessments tie use back to chemical hygiene plans, especially in university or research settings, keeping practitioners, students, and support staff safe from avoidable accidents.

Application Area

Everywhere from industrial plants to advanced research facilities leans on cupric acetate monohydrate. In catalysis, its predictable redox chemistry keeps organic syntheses running smoothly. Farmers once relied on copper acetate-impregnated sprays to halt fungal outbreaks in vineyards, although regulatory headaches over environmental impact have led growers to seek alternatives. As a mordant in textile dyeing, the salt locks color into fabrics, giving rise to greens and blues that antiquarians can still identify centuries later. In the electronics sector, precision etching of printed circuit boards still leverages copper salts, though modern processes watch resource use closely. Laboratory chemists treat it as a reference material for calibration and analysis; these secondary uses, though less glamorous, leave a mark on chemical education, showing students how chemical principles translate into real-world products.

Research & Development

R&D departments have pushed the boundaries for this humble compound well beyond its textbook roots. New copper-based materials for batteries and sensors emerge from manipulating acetate-based precursors, as the molecule’s shape tunes the final material’s surface and performance. The intersection with organic chemistry remains hot, with teams chasing better green chemistry routes for oxidative coupling and carbon-carbon bond formation under mild conditions. Research into single-crystal growth techniques for electronic devices has drawn on cupric acetate monohydrate’s unique solubility and phase-change profile, providing repeatable, defect-free crystals. In the lab, new spectroscopic and analytical standards are using copper acetate to calibrate cutting-edge equipment—an unexpected turn in quality control.

Toxicity Research

Toxicologists caution against careless use, drawing on decades of research that tracks the compound’s behavior in animals and ecosystems. Oral LD50 values for rats hover near 700 mg/kg, documenting moderate acute toxicity. In aquatic systems, copper ions disrupt gill function, leading to population stress in fish at concentrations as low as a few milligrams per liter. Environmental review boards cite lingering soil contamination and runoff hazards as justification for restricting certain agricultural uses. Chronic exposure in humans, even at trace levels, links to gastrointestinal symptoms, anemia, and—at high levels—neuropathy. On job sites, I’ve seen exposure-control measures tighten every few years, driven by both worker advocacy and hard-nosed regulatory oversight. Emphasis on education and prompt reporting of exposure keeps risk in check while not blocking critical research or industrial work.

Future Prospects

The future for cupric acetate monohydrate rides on a balance between its versatility and its environmental footprint. Regulatory scrutiny will keep tightening as evidence of aquatic toxicity and persistent accumulation piles up. Chemists and materials scientists are developing processes to recycle spent copper solutions from etching and catalysis, closing the loop and shrinking the waste stream. The push for smart sensors and green energy tech keeps demand alive, as new copper-based nanomaterials and composite electrodes start out from acetate-based precursors for their controllable morphology. Trends in sustainable agriculture have encouraged a “less is more” approach, using the salt only in high-value crops and under limited conditions. Ultimately, its place depends not only on chemistry, but on community demands for health and sustainability—an ongoing balancing act that shapes how future generations learn, innovate, and solve problems in science and industry.

Taking a Look at Cupric Acetate Monohydrate

Cupric acetate monohydrate sounds like something pulled straight from a chemistry textbook, but this blue-green compound brings its touch to more than labs and beakers. The word “copper” pops up in its name, and for anyone who’s spent time around hardware or gardening stores, copper turns up everywhere from water pipes to slug deterrents. Cupric acetate monohydrate is a different animal, though, and you’ll find it packed in bags and bottles in places most people never see.

Why Factories and Farms Care

Back in my days interning at a small plating shop, I watched workers mix solutions for metal finishing. They didn’t just toss a bit of magic powder into a tank. Their mugs read “Cu(C2H3O2)2·H2O.” This copper salt sits at the core of creating certain finishes. On metals like iron or aluminum, it creates that rich blue-green patina some folks drool over for architectural detail or jewelry. It gives metal a weathered, antique look without waiting for Mother Nature.

Industrial producers also reach for cupric acetate monohydrate when they handle textile dyes. Cotton, especially, soaks up vibrant colors only after a chemical nudge. This copper salt helps lock dye molecules in place by forming stronger chemical bonds, which means that shirt or tablecloth won't fade out after just a few washes.

In the Laboratory and Beyond

For scientists, cupric acetate monohydrate shows up in classrooms and research all the time. Professors pour it into flasks for simple chemical reactions. Those reactions help students see firsthand what copper does as an oxidizer. Some organic chemists even use it as a mild catalyst to build big, complex molecules, especially for pharmaceuticals.

A fun memory: My college roommate tried making his own crystals as a chemistry major, using cupric acetate from the campus lab. The results looked like some lost pirate’s treasure—crystalline formations growing in old jam jars on our windowsill. Kids today still grow copper crystals in science fairs, sparking curiosity about metal ions and solubility.

Greenhouses and Vineyards

The world of agriculture calls on copper compounds to deal with fungus and mold. Grapevines, for instance, fight off downy mildew using copper sprays. Cupric acetate monohydrate goes in some of those mixes. As vineyards face unpredictable weather and tighter pesticide rules, the demand for more controlled, less toxic fungicides keeps rising. Organic farms, too, seek alternatives that fit within stricter guidelines, so copper-based products, used thoughtfully, can help without tainting soil or crops.

Knowledge and Safety Go Together

No one wants surprise toxic hazards. Workers and home experimenters alike wear gloves and goggles around copper salts like cupric acetate monohydrate. Breathing dust or touching it too often can cause health problems. Factories keep strict safety data sheets on hand, and most teachers run safety drills before labs begin. Reading those sheets, honestly, taught me more about practical chemistry than any formula. Keeping people safe while using these chemicals supports trust in everything grown, built, or discovered with copper’s blue-green help.

Moving Toward Better Solutions

Over time, scientists and engineers have pushed for less waste and better recycling during production. Researchers keep testing ways to reuse copper salts or create similar results with lower doses. Universities partner with industry to reduce environmental risks. By sharing experience and results openly, new options reach factories and farms faster. People who grow up experimenting in their kitchens and greenhouses wind up driving real innovation down the line—and that keeps products safer, food cleaner, and science more accessible for everyone.

Understanding the Building Blocks

Most folks know copper as the metal that turns brown pennies green, but it shows up in lab bottles too. Cupric acetate monohydrate crops up in classroom experiments and in industry. Its formula—Cu(CH3COO)2·H2O—speaks for itself. A single copper ion binds with two acetate ions and a water molecule. Toss that on a shelf in any high school chemistry class and it looks like shimmery blue-green crystals. It performs not just as a compound for study, but as a tool in a chemist’s toolkit.

More Than Just Atoms on a Page

My own brush with cupric acetate dates back to undergrad chemistry. The smell in the lab, metallic and sharp, stuck with me. I remember combining copper oxide with acetic acid and watching deep turquoise crystals form. That color pulled everyone’s attention—proof that a simple formula can mean so much more.

When textbooks talk about a formula, they mean a pattern, a recipe. In this one, Cu means copper in the +2 state. The acetate part (CH3COO) wraps itself around the copper. Water—just one molecule—locks in, forming the monohydrate. Neglect the water, and you get a different result. That’s a real point: small bits of chemistry change the way things function.

Why the Details Matter in Real Life

The industrial world leans on these specifics. Paint producers reach for copper salts to create pigments. Farmers use copper mixes to manage fungal growth. The chemical makeup—every single H, O, and C—affects how well the product works. Mess up the water content, cut a corner with the acetates, and things go sideways. Results come out unpredictable, and sometimes dangerous.

Research keeps hammering home how formulas guide outcomes. Take catalysis research. Getting copper acetate monohydrate right means every researcher uses the same starting block. Messy chemistry makes it impossible to compare outcomes. The formula, plain as it looks, brings trust to those shared results.

Challenges in Sourcing and Handling

More than once, I’ve seen people skip over purity and hydration state on bottles in labs. That shortcut tempts, but it’s a shortcut to mistakes. A difference in the number of water molecules creates confusion or outright failure in a process. Some manufacturers address this, but buying from a reputable source remains the best move.

For those who handle the stuff, safety matters, too. Skin contact with copper salts stings. Without gloves and goggles, even a simple spill leads to rash or worse. Safety training, clear labels, and keeping material data sheets close help keep folks safe. Following well-documented guidelines pays off in the long run.

Better Access and Transparency

Digital databases help scientists confirm exactly what they’re buying. Labels with both chemical formula and hydration state bring confidence, not confusion. I’ve grown to appreciate how much smoother a project runs when every bottle says exactly what’s inside. Responsible suppliers who offer rigorous testing and certification let academic and industrial users trust what they see.

Solutions That Stick

Continuous training and easy access to safety information make work safer for everyone. Clear, accurate labeling of copper acetate monohydrate supports both safety and scientific progress. Industry has a real role here, making certainty the norm instead of an extra step.

Why Storage Matters

Cupric acetate monohydrate doesn’t often get flashy headlines, but anyone working in chemical labs, art conservation, or even specialized wood treatments will tell you: careful storage keeps the material safe and useful. Mishandling can lead to product loss, safety risks, or ruined research. So, understanding the basics—straight from the real-world labs and warehouses—matters more than a checklist ever could.

Temperature Makes a Difference

Heat and chemicals don’t mix well. For cupric acetate monohydrate, temperatures in the range of 15°C to 25°C help keep the compound stable. Higher heat speeds up decomposition and changes the material’s appearance. Once, I stored a few jars too close to a sunlit window, and the blue crystals got tacky and started clumping. Months of work and money—lost to a bit of carelessness.

Storing away from direct sunlight and routine temperature swings protects the water locked into the monohydrate. Too much moisture escaping, and you can say goodbye to its reliability as a reagent. Consistent room temperature also reduces any surprise reactions that might harm equipment or users down the line.

Humidity and Air: Friends or Foes?

Moisture in the air turns a well-behaved crystal into a sticky mess. Low humidity is critical. Standard lab desiccators or tightly sealed containers do the trick. Air exposure brings another risk. Cupric acetate monohydrate absorbs water and can draw in other atmospheric contaminants, messing with both chemical purity and results.

Personal experience in a school chemistry stockroom taught me a simple lesson. Even a “barely cracked” lid shortens the shelf life of the stored chemical. Tighten lids and check seals each time. Some labs even toss in packets of silica gel—it’s a small step that pays off long term.

Safe Surfaces and Storage Containers

Glass jars with screw-top lids or chemical-resistant plastics outlast thin poly bags. Avoid metal shelving when possible. Leaky containers can corrode the surface, and a small spill can turn into a serious cleanup job. I’ve seen leaks eat right through unprotected shelving. Store jars upright, and label each clearly. Trying to ID faded or mistyped bottles can lead to dangerous mix-ups.

Separate from Incompatibles

Some chemicals get nasty, fast, when they meet. Keep cupric acetate monohydrate away from strong acids and strong oxidizers. Cross-contamination happens more often than people admit, especially in rushed or cluttered spaces. Designating shelves for different classes of chemicals helps avoid costly or dangerous accidents.

Lab Safety Basics Matter

Personal protection remains a priority. Even seasoned chemists wear gloves and eye protection before handling cupric acetate. The crystalline dust can irritate skin and eyes. Storing products at eye level—rather than high-up, overhead—reduces spills and splashes. Spills on lower shelves are easier to contain and clean.

Most accidents I’ve seen happened not from ignoring the rules, but from trying to save time or space. It pays off to be a bit fussy with storage, whether you’re a university student or a professional technician.

Reducing Waste, Extending Use

Freshness equals value. Using smaller working containers—and refilling from a larger stock as needed—limits the time the chemical spends exposed. Check inventory dates regularly, and cycle through older stock first. Not only does this cut waste, it also makes for safer, more reliable outcomes of every project.

Final Thoughts on Good Storage Practices

Treating cupric acetate monohydrate with respect in storage keeps operations running smoothly, saves money, and reduces risks. Over the years, I’ve learned that a little extra precaution up front is a trade worth making for safe, predictable lab work.

Understanding the Risks

Anyone who's spent time in a science lab or dabbled with chemistry sets probably recognizes cupric acetate monohydrate by its bright blue-green crystals. The stuff shows up in classrooms, plating baths, and sometimes as a pigment. People usually don’t stop to ask: is this compound actually dangerous? Here’s a reality check.

What Happens In the Body

Coins in the pocket carry more risk of copper exposure than this lab salt, but cupric acetate monohydrate isn’t exactly harmless. Swallowing even a gram or two can trigger a rough group of symptoms—nausea, vomiting, stomach pains, and diarrhea. The body doesn’t need a whole lot of copper; too much puts stress on the liver and kidneys. Chronic exposure stresses organs quietly until bigger troubles show up: jaundice, anemia, or even kidney failure. With enough exposure, copper ends up causing cellular damage, mostly by disrupting key enzymes.

Working with the Material

Direct skin contact won’t melt a person’s hand, yet the stuff can cause stains and irritation with a prolonged splash. Eyes fare worse, since the irritation gets amplified and doesn’t fade without rinsing. Breathing in the powder feels bad for the lungs and throat. I remember years ago, a peer in my undergraduate lab let some dust fly. Nobody ended up at the hospital, but that scratchy feeling and bitter metallic taste lingered.

Environmental Impact

Sink drains should never see cupric acetate monohydrate. This copper compound damages aquatic life, killing fish and disrupting invertebrates. In soil, leftover copper messes with root growth and the micro-organisms that keep soil healthy. Any lab or facility dumping this down the pipes risks local regulatory trouble and a visit from environmental health agencies.

Prevention Makes the Difference

Gloves, goggles, and working under proper ventilation take hardly any effort but stop most issues in their tracks. It also helps to keep containers sealed. Labeling everything in plain language lowers the odds of somebody accidentally handling or ingesting the chemical—especially with students or new staff on the scene. My habit: wash hands before lunch in the lab, every time, no matter how busy or late I am. That awkward moment of green stains on a sandwich bread slice was enough to set that lesson.

Looking for Alternatives

Industries have started using less hazardous copper sources for certain applications. In classrooms, copper sulfate often replaces cupric acetate for simple experiments, since it’s more common and straight-forward to handle. If research goals demand cupric acetate, keeping amounts small, and collecting waste, solves most downstream worries. Some companies even invest in closed-loop systems, recycling their copper raw materials to avoid pollution and extra costs.

Building Safer Habits

Reading a safety data sheet before handling chemicals takes fewer than five minutes and avoids most of the headache. My years in teaching taught me that direct training works much better than just handing out safety papers nobody reads. A quick demo or story about a minor spill grabs attention and sticks in the mind, especially for young students.

Cupric acetate monohydrate isn’t the most menacing substance on the shelf, but it deserves respect. Safer habits, vigilance, and replacing it when possible keep science and industry running without making anyone or anything sick in the process.

A Close Look at Its Appearance

Cupric acetate monohydrate grabs your attention right out of the bottle. You notice its bright blue-green crystals, looking almost like shards of colored glass. This substance doesn’t hide—its striking color stands out among the more common white powders in many labs. Years of working with copper compounds have taught me that their color signals purity. In my experience, when the crystals are deep blue-green, you know you have reliable material in your hands without the need for expensive analysis.

It’s easy to dismiss color as something trivial, but in chemistry, it often spells out real information. For students just starting experiments or folks doing scientific demos, cupric acetate monohydrate provides vivid proof of copper’s role. The color also hints at what’s going on inside: copper ions locking in with acetate and water, changing plain old white powder into something you see from across the room.

Straightforward Solubility

This copper salt dissolves very well in water. Pour it into liquid and the blue spreads quickly, coloring the whole mix in a matter of moments. The crystals break down fast, and you won’t see solid chunks floating after a good stir. I’ve used this quality when prepping solutions for copper plating and for making pigment. Back in college, I learned firsthand how helpful a rapidly dissolving material can be—one less thing between you and your finished product.

Solubility tells you more than how a chemical acts in water. It impacts choice and safety across the board. Want to plate a metal? You want a solution, not a sticky mess. Scientists and teachers lean on the simple mixing process to demonstrate copper ions in action, showing just how easily copper jumps from solid to solution. People looking for alternate uses, like making catalysts or stains, pick cupric acetate monohydrate because the color and dissolvability make their work easier and more predictable.

Real-World Applications and Responsible Practices

Easy solubility gives the compound an edge in several fields. In microbiology, copper can act as an antifungal agent—quick dissolving helps the active ingredient get right where it needs to go. In my experience, prepping for any copper-based reaction goes faster because you’re not waiting for hours as with some less reliable salts. People in the arts sometimes use it to form patina on sculptures and jewelry, chasing specific surface colors and textures that only copper compounds deliver.

Of course, quick dissolving also means extra care. It’s tempting to think nothing can go wrong with a blue substance swirling in water, but copper salts in high concentration may harm both health and environment. Always keep gloves on, use proper disposal methods, and don’t pour leftovers down the drain. Labs, schools, and artists need to reinforce those habits.

If anyone’s looking for a fix or safer handling, find tech sheets and trusted supplier documentation. More transparency about composition and potential health impacts helps both the beginner and the seasoned chemist. Teach, watch, and review. These simple habits protect both you and anyone downstream of your sink or drain.

Cupric acetate monohydrate fills its role in science and art because it’s as easy to spot as it is to use. The combination of appearance and speedy dissolving power opens doors for lessons, innovation, and discovery—so long as you respect its strength and keep learning.

| Names | |

| Preferred IUPAC name | Copper(II) acetate monohydrate |

| Other names |

Copper(II) acetate monohydrate

Cupric acetate monohydrate Copper diacetate monohydrate Cu(OAc)2·H2O Copper(II) ethanoate monohydrate |

| Pronunciation | /ˈkjuː.prɪk əˈsiː.teɪt ˌmɒn.oʊˈhaɪ.dreɪt/ |

| Identifiers | |

| CAS Number | 6046-93-1 |

| Beilstein Reference | 1368735 |

| ChEBI | CHEBI:131356 |

| ChEMBL | CHEMBL1233483 |

| ChemSpider | 57811 |

| DrugBank | DB14598 |

| ECHA InfoCard | 03e1fa4b-4b8b-492d-84d5-7e8466c6640e |

| EC Number | 1.10.3.2 |

| Gmelin Reference | 1268 |

| KEGG | C01086 |

| MeSH | D003477 |

| PubChem CID | 164454 |

| RTECS number | AF7400000 |

| UNII | 88X3195PH5 |

| UN number | UN3077 |

| Properties | |

| Chemical formula | Cu(CH₃COO)₂·H₂O |

| Molar mass | 199.65 g/mol |

| Appearance | Blue crystals or crystalline powder |

| Odor | Odorless |

| Density | 1.88 g/cm³ |

| Solubility in water | Soluble in water |

| log P | -2.6 |

| Vapor pressure | Negligible |

| Acidity (pKa) | 4.75 |

| Basicity (pKb) | 6.19 |

| Magnetic susceptibility (χ) | χ = +72.0 × 10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.544 |

| Viscosity | Viscous mass |

| Dipole moment | 0 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 205.0 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -929.0 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -1215 kJ·mol⁻¹ |

| Pharmacology | |

| ATC code | A12CX |

| Hazards | |

| Main hazards | Harmful if swallowed, causes serious eye irritation, may cause respiratory irritation, toxic to aquatic life with long lasting effects |

| GHS labelling | GHS02, GHS07 |

| Pictograms | GHS07,GHS09 |

| Signal word | Warning |

| Hazard statements | H302 + H332: Harmful if swallowed or if inhaled. |

| Precautionary statements | P264, P270, P273, P301+P312, P305+P351+P338, P330, P501 |

| Explosive limits | Not explosive |

| Lethal dose or concentration | LD50 Oral Rat 710 mg/kg |

| LD50 (median dose) | LD50 (oral, rat): 710 mg/kg |

| NIOSH | WA9600000 |

| PEL (Permissible) | PEL (Permissible Exposure Limit) of Cupric Acetate Monohydrate: 1 mg/m³ (as Cu) |

| REL (Recommended) | REL: 0.1 mg(Cu)/m³ |

| Related compounds | |

| Related compounds |

Copper(II) acetate

Copper(II) acetate anhydrous Copper(I) acetate Copper(II) sulfate Copper(II) chloride Copper(II) nitrate Basic copper(II) acetate Acetic acid |