Barium Acetate: A Closer Look at the Element’s Journey and Value

Historical Development

Barium acetate stands as a chemical with roots reaching into the early years of modern chemistry. In the nineteenth century, chemists recognized the usefulness of barium salts and started isolating compounds like barium acetate to meet the needs of industry and science. Acetates grew important for analysis and manufacturing, and barium easily drew attention for its solubility and predictable reactions. Barium acetate’s history tracks alongside the growth of chemical industry in Europe, where glassmaking and dye production depended on additives that could bring out new colors or precise textures. Chemists like Carl Wilhelm Scheele and Sir Humphry Davy, who both studied barium’s potential, recorded details that later shaped industrial processes. Over time, as product safety and handling improved, the compound earned a respected spot in technical circles, holding steady through decades where many other salts fell out of favor.

Product Overview

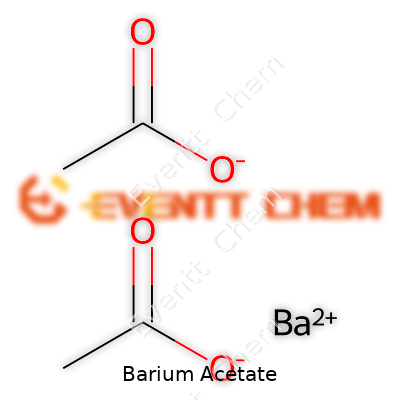

Barium acetate appears as a white, crystalline solid with a sharp, bitter taste. It has a chemical formula of Ba(C2H3O2)2, drawing interest in both academic and industrial sectors. The acetate brings together Ba2+ and two acetate anions, forming a salt used in laboratory work, synthesis, and manufacturing. In the glass industry, it functions as a refining agent. Textile printing operations and dye production also benefit from its presence. Its ability to react with sulfates helps in processes that require sulfate removal. For researchers, barium acetate opens pathways to investigate crystal structure, ionic reactions, and compound modification.

Physical & Chemical Properties

Barium acetate dissolves well in water, producing clear solutions that act as strong electrolytes. The salt melts at roughly 450 °C and decomposes if heated further, breaking down to barium oxide and acetic acid. The solid form tends to be hygroscopic, absorbing water from the air and eventually clumping if left exposed. Compared to other barium salts, its acetate group gives it greater solubility and different reactivity, especially when mixing with metal ions or reacting with sulfate or carbonate sources. The compound appears stable under dry storage and standard pressure, but long-term stability depends on keeping containers sealed and away from moisture.

Technical Specifications & Labeling

Manufacturers supply barium acetate to meet a range of purity levels, depending on need. Analytical-grade material usually claims purity above 99%, with trace metals and alkali content specifically measured. Packaging must show lot number, purity, and supplier information, in compliance with chemical safety regulations. Labels highlight the potential for toxicity, proper storage, and disposal instructions. Safety Data Sheets go along with the product, reporting hazard and first aid measures. Buyers in regions with strict environmental laws check for additional compliance marks, since barium salts face restrictions due to their environmental and health impacts.

Preparation Method

Industrial-scale synthesis of barium acetate relies on combining barium carbonate with acetic acid. This process follows a straightforward route: barium carbonate reacts in warm acetic acid, releasing carbon dioxide as a gas and leaving barium acetate dissolved in solution. Evaporating the liquid allows crystals to form, which are then washed and dried. Some labs use barium hydroxide as a starting material instead, depending on cost or availability, but the carbonate route often prevails due to simple handling and established performance. Batch processes dominate, with quality checked by titration and analysis for contaminants.

Chemical Reactions & Modifications

Barium acetate often serves as a precursor for making other barium compounds, especially barium sulfate and barium carbonate. In reaction with sulfates, it forms a solid barium sulfate precipitate, removing sulfate ions from solution. Mixing with carbon dioxide produces barium carbonate, valuable for ceramics and specialty glass. Its acetate group enters substitution reactions, and under certain conditions, allows for partial hydrolysis or oxidation. Scientists use barium acetate to explore precipitation dynamics in teaching labs, or to create custom mixed-metal salts in research. Its reactivity draws attention because it showcases the predictable chemistry of heavy alkaline earth metals.

Synonyms & Product Names

In commerce and technical documentation, barium acetate carries alternative names such as Acetic acid, barium salt; Barium diacetate; and Acidum aceticum bariatricum. Suppliers sometimes list it under less common trade names, and catalog entries often cite old references to barium ethanoate. The CAS number (543-80-6) and EC number ensure clear identification across borders, which helps coordinate shipping and compliance between suppliers, regulators, and users.

Safety & Operational Standards

Handling barium acetate means respecting its toxicity. The compound, like many barium salts, disrupts potassium channels in nerve and muscle cells, posing an acute poisoning risk if swallowed or inhaled. Operators wear gloves, goggles, and masks; in larger plants, strict ventilation guidelines control airborne dust. Storage requires sealed containers, isolated from acids that might produce hazardous vapors. Emergency procedures stand in place for spills; workers train on neutralizing and cleaning up, using materials that don’t introduce acids. Disposal must follow environmental law, since improper waste handling threatens waterways and wildlife. Inside universities and research centers, chemical hygiene plans include barium salts, with training updated annually.

Application Area

One of the main uses for barium acetate comes in specialty glassmaking, where it acts as a flux to control melting points and improve clarity. Textile companies add it to certain dye baths, taking advantage of its ability to fix or brighten colors. In the analytical chemistry world, workers use it for sulfate removal and cation analysis; in classroom settings, it becomes an easy example of ionic precipitation. Electronics sectors sometimes use barium acetate as a chemical precursor for advanced ceramic capacitors, particularly where barium titanate production matters for new generation devices. Its role can change quickly, depending on market and discovery, but those industries depend on predictable purity and stable sourcing.

Research & Development

Research around barium acetate keeps moving forward, with material scientists exploring new crystal growth pathways, doped ceramic compositions, and catalyst supports. Lab groups study how substituting other ions into its structure might yield new luminescent or conductive materials. Increasingly, environmental labs test its use in remediation, trying to trap sulfate and heavy metals from contaminated water. Patent filings cover new synthesis routes aimed at minimizing waste and improving selectivity. At academic conferences, barium acetate appears in posters about green chemistry, process engineering, and inorganic reaction mechanisms.

Toxicity Research

Toxicology data on barium acetate shows the compound carries risks, mainly due to its solubility and the biological effects of barium itself. Studies in rodents demonstrate neurotoxic and cardiotoxic outcomes after oral dosing, with rapid onset and severe symptoms. Acute poisoning causes hypokalemia, muscle weakness, and sometimes fatal arrhythmias. Environmental studies add another layer, showing that barium ions released to soil or water threaten invertebrate and aquatic populations. That risk pushes ongoing research into antidotes, exposure limits, and cleanup technologies. Regulatory agencies track toxicity tests and update workplace limits as more findings emerge. For consumer-facing products, guidelines ban or sharply restrict use of barium acetate, ensuring occupational exposures stay as low as possible.

Future Prospects

Looking ahead, barium acetate faces new scrutiny and opportunity. Tighter regulations on heavy metals could squeeze demand in some legacy uses, but innovation in energy storage, environmental cleanup, and advanced materials keeps the door open. Researchers look for ways to recover and recycle barium salts from industrial waste streams, turning a liability into a sustainable resource. Glass and ceramic technologies continue to evolve, with barium acetate’s role likely changing as engineers push for higher performance. As trends shift toward greener technology and closed-loop manufacturing, those who work with barium acetate find themselves at the intersection of tradition and change, balancing old expertise with new discovery.

What Makes Barium Acetate Stand Out

Barium acetate, a simple compound made from barium and acetic acid, often gets overlooked in everyday talk. Still, it brings value to several corners of science and industry. Most people likely haven’t come across it unless chemistry class was a favorite subject. My own time in the lab, cleaning glassware and watching reactions, gave me real respect for these basic chemicals that quietly shape a lot of what we take for granted.

The Backbone of Pigments and Dyes

The color in many household and artistic products owes a debt to barium acetate. Pigment manufacturers use it to help create certain types of vivid greens that won’t fade next to sunlight or harsh cleaning. The reason it works has to do with how barium helps stabilize the molecules carrying color, delivering long-lasting results. Without these kinds of salts, our walls and canvases would lose their shine a lot faster.

The Helpful Hand in Laboratories

Chemists keep barium acetate in storerooms for a few reasons. It reacts predictably with some common ions, which makes it reliable for research and analysis. I remember pulling it off the shelf to carry out simple precipitation reactions, separating certain metal ions from solutions to understand their properties. The satisfaction of seeing a solid form right before your eyes—the “aha” moment for chemistry fans—depends on consistent chemicals like this one.

Glass and Ceramics Get a Boost

Barium acetate pops up again in the world of ceramics and specialty glass. During production, it helps control the melting point and appearance of the final product. Without it, pieces might come out looking dull or containing functional flaws. Ceramic glazes, in particular, use barium compounds to produce smooth finishes and certain color effects. This has real-world impact, whether you’re looking at fine dinnerware or tiles covering a subway wall.

A Role in Synthesis and Beyond

Manufacturers also lean on barium acetate to prepare other barium-based chemicals, which themselves prove useful in areas like electronics and advanced materials. These reactions typically occur away from public view, but they set the stage for device manufacturing—what goes into touchscreens and some kinds of sensors, for example.

Recognizing Hazards and Managing Risk

No commentary on barium compounds should skip over safety. Barium acetate can cause harm if people eat it, inhale dust, or absorb it through the skin. Laboratories and factories that handle it routinely rely on protective gear and good ventilation. I’ve seen both tight regulations and a strict emphasis on training—everyone needs to understand the risks, as accidental exposure can be dangerous. Good policy and smart design go far toward keeping people safe.

Looking for Safer Alternatives and Smarter Handling

Progress continues in finding safer compounds or adjusting processes to cut down on toxic exposure. In many cases, swapping out barium acetate in consumer-facing applications reduces risk. Companies also shift to closed-system production or add more rigorous waste management, which lessens environmental impact and human health dangers. These adjustments often pay off over time, keeping workplaces safer and products more sustainable.

The Takeaway

Barium acetate rarely grabs headlines or sparks big debates, but its role runs across industries that matter in daily life. Urging better handling and greener alternatives marks a clear path forward. My own experience in the lab taught me that the small choices chemistry makes—around safety, sourcing, and use—add up to real differences in people’s lives.

The Toxic Side of Barium Acetate

Barium acetate grabs your attention with its sleek white crystals and lab-friendly nature, but lurking behind its clean look is a level of toxicity most people overlook. Take a quick glance at a safety sheet and you will see a warning about poisoning risk. That's not just legal red tape—it’s a real concern rooted in chemistry, biology, and years of recorded incidents.

This compound holds a spot among soluble barium salts. When barium enters the body, it interferes with muscle functions, especially in the heart. Ingest enough, and you risk muscle paralysis, serious heart arrhythmias, or even sudden death. There are stories in the literature—people mishandling it in labs, kids accidentally exposed from improperly stored chemicals—where symptoms like vomiting, diarrhea, muscle weakness, and confusion came on fast. Every chemistry teacher I’ve met drills in the “don’t touch, don’t taste, don’t inhale” mantra for good reason.

Why These Risks Matter in Real Life

The problem isn’t just confined to laboratories. Barium acetate gets used in making other chemicals, textile mordants, and spark plug lubricants, often in places where training can be spotty or supervision limited. Workers might trust dusty gloves or old goggles instead of using respirators and full eye protection. Years back, I watched a simple mistake in a university prep lab—a technician poured it without a fume hood. The dust drifted before drifting down. Nobody got sick, but it was a close call. A bit of hot coffee, some sneezing, and you could be absorbing barium without knowing it.

Natural barium in soil poses less risk because it isn’t that soluble. Processing it into something like acetate ratchets up the danger. Once it dissolves, it can enter the bloodstream more easily. Treating barium poisoning isn’t easy or cheap, either. You need to give specific compounds (like sulfate or magnesium) to bind it in the gut and keep it from spreading, followed by days of monitoring key organs. Healthcare workers have protocols, but in small clinics or improvised situations, that gets difficult, to say nothing of places without skilled toxicologists.

Fact-Based Solutions and Safer Handling

Ignoring safety rules isn’t just careless, it’s costly. Data from workplace safety agencies shows even a single exposure can lead to long-term problems. Most accidental cases stem from inadequate labeling, poor ventilation, or skipped steps. The fix starts with requiring clear, sensible labels—not jargon-bound so that younger or non-native speakers miss the main point. Color codes and pictograms help where language barriers exist. Facilities have to enforce glove, mask, and eyewear rules strictly, not just toss a checklist on the wall. Training sessions should use real accident stories to drive home the message.

On a policy level, regulators have room to make sure old labs and storage areas keep up with modern rules. Too many small manufacturers rely on leftover supplies and outdated safety plans. Inspection schedules should be more regular, and disposal procedures need updating to prevent contaminants from leaching into groundwater or crops.

In households, nobody should buy or store compounds like barium acetate unless they are trained to handle them. Google searches sometimes make poisons sound easy to experiment with, but there’s a reason these aren’t on hardware store shelves.

The Bottom Line: Knowledge Saves Lives

Barium acetate’s dangers come from its solubility and the way it attacks the body’s electrical and muscular systems. It’s not just another bottle on a shelf—it’s a compound that demands respect, protective gear, and smart policies. Whenever people ask about toxic chemicals, I remember the close calls and small mistakes that add up. Safety isn’t an abstract idea. With barium acetate, lives depend on it.

The Formula and What it Means

Barium acetate, a compound that shows up in both the classroom and the laboratory, carries the chemical formula Ba(C2H3O2)2. For anyone who remembers a bit of high school chemistry, barium sits on the periodic table with a 2+ charge, while the acetate ion comes with a single negative charge. It takes two acetate ions to balance out one barium ion — that sets up this formula. This isn’t just about balancing equations or passing tests. Understanding these formulas helps lay the groundwork for problem-solving in all sorts of scientific work. Even outside the science lab, a little chemical literacy can help spot misleading claims in ads or products.

Ties to Everyday Life

Barium acetate doesn’t make headlines often — it doesn’t find its way into many household items. Still, it represents something important about chemistry. Many people worry about chemicals showing up in water, food, and consumer goods. Knowing how to decode a formula or look up safety information helps you make smarter choices. Barium acetate appears in some chemical analysis work and even in textile printing. Left unchecked or misused, compounds containing barium can bring health risks if handled carelessly. Chronic exposure to soluble barium compounds triggers muscle weakness, breathing difficulty, or in extreme cases, paralysis. Acetates as a group appear in food and industry, but they don’t always share the same safety profile.

Real Risks, Real Solutions

Chemical spills and poor handling practices create problems for workers and communities. Years ago, I worked in a research lab where we handled a range of chemicals, including barium salts. Spills and waste called for real attention — haphazard cleanup meant putting everyone at risk. Safety data sheets, proper labeling, and training make a huge difference. That’s not overkill; it’s common sense born from real-world accidents. In many cases, chemical names sound the same, so checking the actual formula matters. Ba(C2H3O2)2 isn’t the same as barium chloride or barium sulfate. Each one behaves differently in water, the body, or the environment.

Why Accuracy Counts

Error creeps in easily — I’ve seen it happen more times than I’d like to admit. Mixing up barium acetate with something like calcium acetate doesn’t just derail an experiment, it can feed the kind of misinformation that spreads quickly online. Accuracy matters in science and reporting. Citing sources like the National Center for Biotechnology Information (NCBI) or peer-reviewed journals builds trust, and it’s something I practice daily. If you’re teaching, learning, or reporting on science, a moment spent double-checking a chemical formula or data point beats hours spent correcting misinformation later.

Building Chemical Awareness

You don’t need a PhD to benefit from chemical knowledge. Understanding formulas like that of barium acetate opens doors to smarter questions and better conversations. Chemistry textbooks and open-access resources, including PubChem and the Centers for Disease Control’s Chemical Database, give people tools to check claims and explore chemistry’s everyday relevance. There’s value in being able to look past complicated names and see what’s really there. In a world where chemical language pops up in news, science, and even marketing, a little attention to formulas like Ba(C2H3O2)2 pays off every day.

Understanding the Risks of Barium Acetate

Barium acetate isn’t something most people keep in the kitchen cupboard. It’s a solid white salt, sometimes used in scientific research, chemical synthesis, and educational labs. It looks harmless at a glance, but looks deceive—this compound carries real hazards. Ingestion, inhalation, even simple skin contact can result in serious health issues. My own years spent working around lab chemicals have made me careful, often bordering on overcautious. Yet with something like barium acetate, extra steps don’t just keep you safe—they keep anyone nearby safe as well. The biggest worry comes from its toxicity to humans and animals, and even a small mistake like a leaky container can spell danger.

Setting Up a Safe Storage Area

There’s no shortcut when it comes to storage space. It’s not enough to toss the container on a shelf and call it good. Barium acetate stays best in a cool, dry place, away from anything that might cause a reaction—like acids or moisture. Humidity encourages clumping and, more importantly, can make the chemical break down into hazardous byproducts. I’ve seen what happens when water finds its way into a supposedly sealed chemical bottle—the result is always a headache, sometimes much worse. By keeping it in airtight containers, sealed tightly every time, you cut down risk substantially.

Metal cabinets lined with non-reactive material have become the go-to in most labs I’ve seen. The reason: barium acetate can corrode some metals over time. Properly labeled, chemical-resistant containers earn their keep, especially if spills occur. Make sure to always store it above the floor—never low or at ground level where a small amount of water could creep in unnoticed.

Labeling and Segregation—Simple but Critical

Labels save lives. Forget creativity and focus on clarity: the name, concentration, hazard information, and date. Barium acetate has no business mingling with food, or even being in a refrigerator used for anything edible. I once encountered a lab where unlabeled jars shared a shelf, and sorting it out took hours—and felt genuinely risky. Keep it separated from acids, and don’t let curiosity (or carelessness) tempt you to store different chemicals in the same area. Fumes mix, residues interact, and one bad day can lead to lasting harm.

Building Strong Habits in Handling

Barium acetate invites caution because mistakes escalate quickly. Spills, even dry, should be seen as an emergency. Use gloves and goggles every single time, not just when pouring a new batch or discarding an old one. I always wash my hands after handling, no exceptions. Safety isn’t just about regulations or annual checks—it’s the day-to-day discipline that decides whether people go home healthy.

Disposal and Training: The Often Overlooked Factors

I’ve witnessed confusion take hold when chemicals reach the end of their useful life. Leaving old barium acetate to gather dust is never safe. Workplaces with well-trained employees, clear disposal processes, and access to proper hazardous waste collection never have such issues. Training doesn’t have to be a massive production: a straightforward session on barium toxicity and emergency procedures makes all the difference, especially for younger staff or students.

Chemicals like barium acetate demand respect. By treating storage as a task worth thoughtful attention, not a chore to rush through, everyone in the workplace or classroom stays safer. The quiet investment in good habits and clear organization pays off every single day.

The Real Risks Behind the Compound

Barium acetate, a white crystalline salt, doesn't get much attention outside of labs, but it carries real danger that’s easy to overlook. I remember working as a lab tech early on, and the phrase “treat every unfamiliar bottle as if it could blind you” always stuck with me. That attitude shaped how I view compounds like barium acetate. This chemical can cause serious harm—mainly because barium inside the body messes with muscle and nerve function, and even small amounts spell trouble for the heart and kidneys. Touching it or breathing its dust or getting it in your eyes is asking for trouble, so a sharp focus on handling makes the difference between science and an accident report.

Understanding Exposure: Not Just Spills and Dust

Many people picture big spills or clouds of powder as the only threat. But just opening a bag or transferring a scoop from one jar to another can release enough dust to pose a risk. Barium compounds get absorbed through the skin and lungs, so skipping gloves or a mask just "once" might be enough for acute poisoning. Washing up before lunch becomes more than routine—without it, barium travels from your skin right into a sandwich. Common sense tells you not to eat where you work with this stuff, but the unlucky ones ignored these basics and paid for it in the ER.

Protective Gear: Not Just For Show

Every lab worth its salt stocks goggles, gloves, and approved chemical-resistant coats. Nitrile or latex gloves work for short handling, but some folks need thicker gear if spills look likely or if large amounts need to move. A face shield and well-fitting goggles stop powder or accidental splashes from hitting your eyes. Basic surgical masks don’t trap fine chemical dust, so a good respirator makes a difference. I keep my own pair stashed with my lab badge—no mask, no entry. For added safety, closed shoes and long pants put some distance between skin and chemical.

Keeping Clean: Hygiene and Housekeeping

Rushing cleanup is a major mistake. Barium acetate settles on benches and gear, then turns up on door handles and pens. Regular surface wipe-downs with damp clothes (not dry sweeping) keeps dust down. Dirty gloves should never touch anything not required for the experiment. Signage reminds everyone what’s in play, and clear labeling ends the “what’s this powder?” guesswork.

What To Do About Small Spills and Accidents

No one likes a panic, but spills happen fast. The best labs have spill kits ready with absorbent materials. Don’t wash the barium down the drain—it can hit the water supply and then things get ugly for everyone. Scrape up powders, soak up liquids, and seal them into waste bags. Alert your supervisor right away. Think of it as protecting the next shift and the cleaners, not just covering your own back.

Handling Mistakes: Immediate Response Matters

If barium acetate lands on skin, head straight for the sink and wash it off with lots of water. If it gets in your eyes, flushed water for at least fifteen minutes works best; don’t rub the eye or wait. If someone reports numbness, dizziness, or muscle cramps after working with barium compounds, get medical help right away—the clock ticks fast with this sort of poisoning.

Better Habits, Safer Workplaces

Training never stops. I found that new staff pick up safety habits from older workers. Mistakes get repeated when shortcuts get passed down. A culture where anyone can speak up about unsafe behavior or failing safety gear saves more people than any poster or memo. Stopping for a safety chat before opening containers brings the risks back to the front of everyone’s mind. Barium acetate might seem minor next to other chemicals, but the cost of slipping up sticks with people long after the jar's gone.

| Names | |

| Preferred IUPAC name | Barium ethanoate |

| Other names |

Acetic acid, barium salt

Barium(II) acetate |

| Pronunciation | /ˈbɛəriəm ˈæsɪteɪt/ |

| Identifiers | |

| CAS Number | 543-80-6 |

| Beilstein Reference | 80357 |

| ChEBI | CHEBI:33361 |

| ChEMBL | CHEMBL3381476 |

| ChemSpider | 11614 |

| DrugBank | DB11150 |

| ECHA InfoCard | 100.035.133 |

| EC Number | 56-35-1 |

| Gmelin Reference | 5827 |

| KEGG | C13921 |

| MeSH | D001477 |

| PubChem CID | 24863973 |

| RTECS number | AF8575000 |

| UNII | UQ85T17A0T |

| UN number | UN1564 |

| Properties | |

| Chemical formula | Ba(C2H3O2)2 |

| Molar mass | 255.42 g/mol |

| Appearance | White powder |

| Odor | Odorless |

| Density | 2.46 g/cm³ |

| Solubility in water | 5.6 g/100 mL (20 °C) |

| log P | -2.06 |

| Vapor pressure | 0 mmHg (25°C) |

| Acidity (pKa) | 4.76 |

| Basicity (pKb) | 2.78 |

| Magnetic susceptibility (χ) | Magnetic susceptibility (χ): -59.0×10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.576 |

| Dipole moment | 0 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 212.7 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -1011.0 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -1767.7 kJ/mol |

| Pharmacology | |

| ATC code | V09AA02 |

| Hazards | |

| Main hazards | Harmful if swallowed, causes serious eye irritation, may cause respiratory irritation. |

| GHS labelling | GHS02, GHS07 |

| Pictograms | GHS02,GHS07 |

| Signal word | Warning |

| Hazard statements | H302, H332 |

| Precautionary statements | P264, P270, P301+P312, P330, P501 |

| NFPA 704 (fire diamond) | 2-0-0 |

| Lethal dose or concentration | LD50 oral (rat): 921 mg/kg |

| LD50 (median dose) | LD50 (median dose): Oral (rat) 920 mg/kg |

| NIOSH | CAS No. 543-80-6 |

| PEL (Permissible) | PEL (Permissible Exposure Limit) for Barium Acetate: "0.5 mg/m3 (as Ba) |

| REL (Recommended) | 0.5 mg/m³ |

| IDLH (Immediate danger) | 50 mg/m³ |

| Related compounds | |

| Related compounds |

Acetic acid

Barium carbonate Barium chloride |