2-Ethylhexyl Acetate: Tracks Through Industry and Research

Historical Development

Back in the middle of the twentieth century, chemists saw a need for more reliable, safe, and versatile solvents in everything from paints to printing inks. The shift away from volatile, pungent solvents toward those with better odor and slower evaporation drove industrial labs to explore alternatives. 2-Ethylhexyl acetate started appearing in patents and academic papers around the '40s and '50s, showing promise as a balancing act between strong solvency and manageable volatility. As chemical regulation tightened, manufacturers searching for solutions less aggressive on both people and the atmosphere leaned into compounds like 2-ethylhexyl acetate, which could offer application benefits without landing on hazardous materials lists. This change pushed 2-ethylhexyl acetate from a specialty item into wide-scale adoption across coatings, nail polish removers, and certain agrochemical blends. Over decades, companies have refined production and handling practices, making this chemical both more available and safer to use, reflecting a broader trend in the chemical industry toward solutions with clear safety and performance profiles.

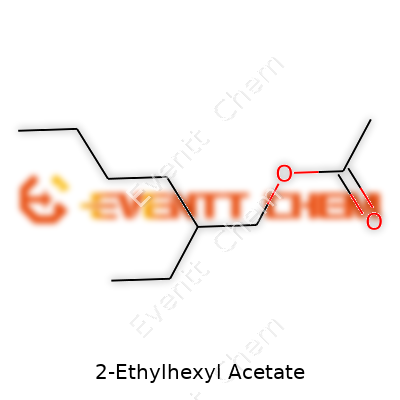

Product Overview

2-Ethylhexyl acetate is a colorless liquid with a pleasant, mildly fruity odor that sets it apart from harsher industrial solvents. Its chemical formula, C10H20O2, means it's neither the lightest nor the heaviest in the ester family. It's found in high-grade paints, lacquers, and specialty coatings, with the ability to dissolve both polar and non-polar substances thanks to its balance of hydrocarbon backbone and ester group. The ease of blending with other solvents, combined with low water solubility, means it can work in formulations that need to avoid water pickup or hydrolysis. Its slow evaporation rate stands out in cellulosic or acrylic lacquers where more working time is vital, as fast-drying alternatives often lead to brush lines or film defects.

Physical & Chemical Properties

The fluidity and stability of 2-ethylhexyl acetate come from its unique molecular structure. It appears as a clear liquid, boiling at about 211°C and freezing well below ambient temperature, so it stays liquid year-round. The density sits around 0.87 g/cm³ at room temperature, and the vapor pressure hovers low enough to keep evaporation modest under regular conditions. Most lab technicians appreciate its flash point of 87°C, reducing the fire risk compared to traditional ethers or acetates. Chemically, it's mildly reactive – it doesn't break down fast under typical storage, provided the containers keep out moisture and acids. Its low water solubility, roughly 0.7g/L at 20°C, makes it easier to handle in systems where hydrolysis could ruin a batch. These indicators match what I've seen in lab settings: technicians store and use this compound without the constant worry that follows some volatile organics.

Technical Specifications & Labeling

Labeling requirements for 2-ethylhexyl acetate have grown stricter in the past decade. Global labeling systems, such as GHS, list it as an irritant with clear pictograms required for workplace safety. Technical specs from suppliers focus on purity, water content, acidity, and color. Most reputable suppliers quote purity above 98%, water content below 0.1%, and acidity as acetic acid under 0.01%. The color must not exceed 10 on the Hazen/APHA scale, assuring no interference in color-critical applications like white or clear coatings. Documented shelf life, typically at least twelve months sealed, depends mostly on protection from acidic or basic contamination and moisture ingress. This paperwork runs hand-in-hand with Safety Data Sheets, all lined up with local regulations to help buyers track compliance and safe use in regulated fields like automotive and consumer products.

Preparation Method

Most commercial production relies on Fischer esterification. Chemists react 2-ethylhexanol with acetic acid under an acid catalyst, like sulfuric acid, with water as a by-product. Companies continuously remove water to push the reaction toward completion, using techniques such as azeotropic distillation with toluene or xylene as agents helping separate water from the reaction mixture. After completion, the reaction mass goes through neutralization, water washing to remove any acid leftover, and then fractionation distillation to separate the 2-ethylhexyl acetate from unreacted starting materials and low-boiling by-products. This approach uses modest temperatures and pressures, making it safer and cheaper on an industrial scale. Equipment needs heavy corrosion resistance and good temperature control due to the acidity and strong ester odors involved. Process engineers who’ve worked on this system often point out the robust yields and minimal waste compared to older ester synthesis methods.

Chemical Reactions & Modifications

Besides acting as a solvent, 2-ethylhexyl acetate offers a platform for further alterations. The ester group can undergo hydrolysis if exposed to acids, bases, or strong nucleophiles, breaking it into 2-ethylhexanol and acetic acid. Nitration or halogenation remains rare under standard conditions due to the poor reactivity of the saturated carbon backbone, but under specific circumstances, chemists can use the acetate group to anchor other modifications in synthetic organic chemistry. Laboratories sometimes leverage this flexibility in multi-step synthesis, attaching or removing the acetate as needed. The compound’s relative inertness toward oxidation or reduction lets it sit alongside more sensitive components without side reactions, a feature appreciated in complex mixtures and intermediates for agrochemical research.

Synonyms & Product Names

Chemists and suppliers know 2-ethylhexyl acetate by many names: Isooctyl acetate, 2-EHA, octan-2-yl acetate, and even acetic acid 2-ethylhexyl ester. Catalogues often list it under CAS number 103-09-3. This array of naming pops up across regions. In the United States and Europe, both 2-Ethylhexyl Acetate and Isooctyl Acetate show up on safety data and shipping records, while Asian suppliers sometimes prefer shortened versions or translations. Whether buying in drums or lab bottles, these synonyms help buyers connect international purchases to local safety documentation and ensure that incompatible chemicals do not get mixed in error.

Safety & Operational Standards

Safety management for 2-ethylhexyl acetate in plants and labs focuses on ventilation, skin protection, splash goggles, and chemical-resistant gloves due to its mild irritant nature. It's flammable but less so than lighter ethers or acetates, so standard solvent-handling rules for storage and spill management cover most risks. Facilities using large quantities follow OSHA and REACH requirements, with solvent-specific measures for spill containment and fire response. Employee training walks through material safety data sheets and emergency measures, and storage containers usually sport flame-retardant linings and tight seals to keep out moisture and air. Over years of chemical handling, teams who work with this compound learn to rely on strict labeling and routine inspection to catch leaks or container degradation before they become a problem.

Application Area

Paint and coatings industries value 2-ethylhexyl acetate as a slow-evaporating solvent in nitrocellulose, acrylic, and alkyd formulations, helping produce smooth finishes without brush marks. Nail polish manufacturers use it for its compatibility with resins and reduced sharp odor, improving both worker comfort and product scent. In inks, it acts as a carrier that extends drying and working times, crucial for high-precision printing on sensitive substrates. Agrochemical companies sometimes add it to emulsifiable concentrates where solvency with diverse active ingredients matters. Beyond that, certain electrolytic capacitor and adhesive manufacturers use it as a processing aid during production—especially where solvent residues could interfere with function. Its role in chemical analysis also crops up, since its reactivity profile makes it a decent reference in chromatographic studies.

Research & Development

Shifts in environmental regulation and green chemistry have nudged research labs to re-examine 2-ethylhexyl acetate. Some look for ways to make it from renewable resources, like fermenting bio-ethanol to 2-ethylhexanol and coupling it with bio-based acetic acid. Others test new blend combinations with alternative solvents to cut VOC emissions in coatings without losing gloss or durability. Research teams explore ways to recycle process waste or recover and purify spent solvent with less energy. In chemical synthesis, modified 2-ethylhexyl acetates pop up as intermediates for custom-tuned agrochemicals, where researchers want to fine-tune solubility and volatility. All this innovation keeps the compound in the mix, even as regulatory pressures mount to swap out older, riskier solvents across sectors.

Toxicity Research

Extensive laboratory studies have kept a close watch on potential risks from both acute and chronic exposure to 2-ethylhexyl acetate. Standard inhalation and skin contact tests generally show only mild, reversible irritation at high doses, a contrast to far more aggressive acetates like n-butyl or methyl acetate. Animal studies did not flag carcinogenicity or organ toxicity at exposure levels common in workplace air, and researchers did not see genotoxicity in microbial assays or mammalian cells. Chronic exposure studies, spanning from rodents to routine workplace monitoring, echo this low-to-moderate risk profile, provided ventilation and exposure guidelines are met. Regulatory agencies have kept permissible exposure limits relatively high in comparison to lower-boiling solvents, but continued studies address gaps around sensitive groups, such as pregnant workers and those with respiratory conditions. Environmental persistence runs low, as the compound breaks down by hydrolysis and biodegradation over weeks if released.

Future Prospects

As industries keep shifting toward greener chemistries, the future of 2-ethylhexyl acetate doesn’t just hang on cost or legacy. Research into bio-based and recycled materials may open the door to low-impact manufacturing pipelines. Coatings and polymers that call for both performance and sustainability keep this chemical near the shortlist. Advances in in-situ monitoring and quality control in coatings production let suppliers set ever-tighter specs, so researchers keep tweaking production for both yield and purity improvement. Emerging fields such as advanced printing and electronics may discover new uses for 2-ethylhexyl acetate in both fabrication and cleaning applications. Regulatory frameworks, likely to tighten around VOCs and hazardous solvents, can drive innovation—pushing suppliers to square traditional performance with new, responsible sourcing and disposal methods.

The Everyday Ingredient Nobody Notices

2-Ethylhexyl acetate flies under the radar in daily life, but most folks cross paths with it more often than expected. It’s a colorless, sweet-smelling liquid. I caught its scent long before I knew its name, back when painting my old bedroom and helping family strip varnish off a beat-up table. Both activities felt routine, but the science behind them took me by surprise later in life.

Paints and Coatings: Where Performance and Experience Meet

Step into any home improvement store’s paint aisle. Inside those cans sits a cocktail of chemicals, and 2-ethylhexyl acetate shows up as a key player. Paint engineers favor it because it doesn’t dry too quickly, letting workers brush and roll without fighting sticky, half-cured paint. Painters see fewer brush marks, better coverage, and smooth edges. Less frustration, better results. Products perform well on door frames and wall trims alike, with drying times matching real-world schedules.

Thinners for Artisans and Professionals

Artists and tradespeople using oil-based varnishes benefit from this solvent. If you’ve ever tried thinning furniture polish and got a noseful of strong odor, you’ll find 2-ethylhexyl acetate more pleasant. Furniture refinishers use it because it balances solvency with reduced irritation. Less eye and respiratory sting makes for a nicer workshop.

The World of Printing Inks

Open a pack of magazines or glossy packaging and you might notice a faint, fruity aroma. Printing companies turn to this chemical to help inks flow easily over rollers and sheets, especially in high-speed commercial presses. It helps printed colors pop and stay sharp. The ink sets just right, avoiding blotches and smears that used to be common with other solvents.

Fragrances, Flavors, and Product Safety

2-ethylhexyl acetate pops up in some fragrance formulas and flavor enhancers. Some fruit flavorings and perfumes owe their undertones to this chemical. Even though it isn’t widely known to consumers, toxicology research shows it breaks down quickly in the environment and doesn’t linger in the body. That transparency reassures people like me, who read ingredient labels with a skeptical eye. The European Chemicals Agency and the U.S. Environmental Protection Agency both monitor it for workplace exposure, and current studies haven’t shown worrying effects at typical levels.

Health and Environmental Responsibility

Still, every chemical in wide use deserves scrutiny. Painters and printers need solid ventilation, not just for 2-ethylhexyl acetate but for everything floating through the air in a workshop. Gloved hands and a cracked window do more good than most folks realize. Companies develop water-based paints partly to skip some classic solvents. But sometimes, alternatives can’t match the standards set by older formulas, so safe handling counts for a lot.

Looking Ahead: Smarter Choices for a Safer World

Innovation doesn’t stop. Some labs research plant-based or biodegradable replacements. Until something comes along with the same mix of flexibility, affordability, and practical performance, 2-ethylhexyl acetate holds its place. For workers, it pays to look up chemical safety sheets and talk with experienced contractors. Companies have a responsibility too. Honest labeling, accessible health information, and continued refinement in manufacturing all make a difference.

Everyday Uses and Where You’ll Find It

Open a can of paint, check a bottle of polish, or look at some glues, and odds are you’re dealing with 2-ethylhexyl acetate. Industry folks value this solvent for its low odor and quick evaporation. I’ve spent enough time around workshop benches to know how common it is in finishes, inks, and adhesives. Like plenty of chemicals, people want to know: is this one something to stress over or can you go about your day?

Looking at Hazards Without the Hype

Turn to the safety sheet: they’ll tell you this chemical can irritate eyes and skin and make you feel lightheaded if you breathe lots of vapors. Occupational Safety and Health Administration (OSHA) and the National Institute for Occupational Safety and Health (NIOSH) flag it as an irritant, but it’s not a known cancer risk or a major player in long-term health issues for casual users. Most folks in labs and plants keep their distance, use ventilation, and slap on gloves to avoid the day-after headaches.

Headaches, nausea, or a burning nose signals too much exposure. The body breaks it down quickly, passing most of it out within a day. Animal tests used higher doses than people would ever see at home or work, and even those showed minor effects—a bit of liver swelling in rats, no tumors, no birth defects. Research so far hasn’t connected routine exposure to the health scares that come with tougher solvents or heavy metals.

Real-World Risks and What Matters Most

Lab talk only means so much. In the shop or at home, real risk shows up when ventilation disappears. Pouring a whole drum indoors or rubbing it on bare skin—those are ways to invite trouble. Splashing a little on your hands and washing them soon after lessens problems. For paints and coatings, faint smog-forming chemicals float off, but nowhere near the levels that gasoline or paint thinners toss around.

Companies mark drums flammable not because fire is likely, but because fumes can catch under the right (wrong) conditions. A spark in a closed space full of solvent vapors can end a day fast. I’ve always kept fans running and solvents capped, plain habits that avoid trouble, not just with this one but anything in a painter’s box.

Meeting Safety Standards

European and US agencies set exposure limits far above what anyone sees using these products briefly or in open rooms. I’ve read through air-monitoring data in industrial settings; nothing stands out unless someone spills a barrel or stays in a fume cloud for hours. Teachers, artists, carpenters—they might smell it, but they’re not hitting those high-end exposures. Still, if you’re spraying paint or running machines, a mask and gloves cost less than a hospital visit.

Reducing Risks Without Drama

Solvents like 2-ethylhexyl acetate bring industrial convenience but don’t call for mystery or panic. Fresh air stops most problems before they start. Gloves and goggles matter. Training people to read signs and wash up—those basics tackle nine out of ten safety worries. For workplaces where barrels flow daily, continuous air testing and spill procedures keep surprises down. Green chemistry might swap out some old solvents, but for now, this chemical holds a middling spot on the hazard scale—respect it, don’t fear it.

Getting to Know the Liquid

2-Ethylhexyl acetate shows up as a clear, colorless liquid with only a faint, sweet odor. Over the years, I’ve worked around paints and coatings, and this chemical stands out for being pleasant in smell compared to other industrial solvents that can clear a room. Its mild scent doesn't mean it’s harmless, though. Adequate ventilation remains crucial anywhere it’s used.

Boiling and Freezing Points Matter

With a boiling point near 186°C (367°F), 2-ethylhexyl acetate won’t turn into vapor under most everyday conditions. This property helps it stay present in slow-drying products, which is one reason manufacturers like using it in specialty coatings or inks that can’t afford to flash off too fast. Its freezing point drops to about -70°C (-94°F), so cold storage rarely turns it to solid. In laboratories and factories, that wide temperature flexibility makes handling and transport much easier, because you aren’t dealing with tricky temperature controls to keep it usable.

Evaporation and Density

Evaporation changes the game for solvents. 2-Ethylhexyl acetate evaporates slower than many old-school solvents—such as ethyl acetate or butyl acetate. Folks working with varnishes or lacquers appreciate a slower evaporation rate for a smoother finish and better control. Density lands near 0.87 g/cm³ at room temperature. That’s lighter than water, so spills float. If a drum leaks at a jobsite, the solvent will spread quickly over puddles, reminding crews to keep their secondary containment ready and not skip training on chemical handling.

Solubility Makes It Versatile

Water hates mixing with this chemical—scientists call it “practically insoluble.” This makes it ideal where moisture could ruin a process, like in oil-based paints or industrial cleaners. Yet it dissolves many organic materials, so it fits right into formulations for adhesives, flavors, fragrances, and plasticizers. Most chemists see value in having solvents that don’t surrender their performance to a little humidity.

Flammability: Not to Take Lightly

Even if the flash point runs fairly high—about 77°C (171°F)—it still catches fire under the wrong circumstances. That says keep open flames and sparks far away. A shop storing drums of 2-ethylhexyl acetate must follow fire codes, invest in grounded containers, and build good habits among staff. I’ve heard of warehouses where labels faded away and fumes built up, leading to small fires that could have been avoided with basic housekeeping and attention. Good labeling and storage rules aren't optional extras here.

Beyond the Basics—Handling and Health

Grease splashes can spread, but skin contact won’t burn you right away; that often breeds overconfidence, but eye irritation and headaches quickly remind people not to get careless. Always using gloves, goggles, and smart ventilation makes a difference in keeping safe. Companies that make safety part of the routine rarely report the kinds of accidents that pop up wherever complacency sneaks in.

Addressing Safety and Environmental Impact

Spills demand a swift and careful response. Because 2-ethylhexyl acetate floats, it travels easily on water. Absorbent materials meant for oil work best here. Proper disposal—never pouring down drains—protects local water and wildlife. Even simple things like spill kits and clear cleanup plans show a lot about a company’s commitment to both workers and its neighborhood.

Real Risks, Real Responsibility

I’ve seen too many mishaps in labs and storage rooms to treat chemicals lightly. 2-Ethylhexyl Acetate doesn’t look or smell alarming at first glance, yet this clear liquid hides flammable and irritant properties. If handled carelessly, it can disrupt workflows and cause emergencies. The Material Safety Data Sheet doesn’t just sit in a drawer for a reason—understanding the real-world impact keeps people and property protected.

Locking Down Storage

A drum of this stuff doesn’t belong just anywhere. Workers should always pick a cool, well-ventilated spot, away from sunlight and anything that could spark. I’ve seen what happens when solvents share shelves with oxidizers—bad news every time. Fire codes make it clear: keep containers off the ground, far from heat, and use flame-proof storage cabinets when possible. Spill containment mats and secondary trays make sure leaks don’t spread; years of small slipups have taught me a small drip can travel fast.

Personal Protection Isn’t Optional

My first job in an industrial setting taught me to respect personal protective equipment. People get lazy or cocky, but the moment skin meets even a splash, irritation follows. Safety glasses, chemical-resistant gloves, and sturdy aprons form the basics. Anyone moving or measuring this solvent should know the eyewash and shower locations. Ventilation fans run for a reason—the vapors find their way into lungs and can cause headaches or dizziness before you realize there’s a problem.

Sensible Handling Practices

Pouring or transferring 2-Ethylhexyl Acetate takes finesse. I tell new staff: tight-fitting lids, careful lifting, and small transfers keep the liquid contained. Static sparks around plastic drums have started more than one fire in the industry, so grounding and bonding containers becomes a simple habit. Only properly labeled containers avoid confusion, and double checks on labels keep accidents at bay. Training everyone on emergency procedures means nobody freezes if a spill happens.

Big Picture: Protecting Health, Environment, and Operations

Accidental releases don’t just damage the workplace—they pose a threat to water and soil nearby if drains aren’t controlled. Spill kits with absorbent pads and special disposal drums help manage unexpected leaks. Hazardous waste rules stop people from pouring leftovers down the sink; collection and proper disposal methods shield both the company and the planet.

Mistakes cost thousands in downtime, fines, and sometimes lives. Sharing these lessons and following the facts—long-term exposure research, strict OSHA guidelines, and local fire code—keeps operations smooth and people safe. Giving the right training, using the right storage cabinets, wearing dependable personal protection—it all stacks up to a responsible shop or lab. In the bigger scheme, care with chemicals like 2-Ethylhexyl Acetate shows a respect for skilled work and a promise to send everyone home in the same shape they arrived.

A Flexible Solvent in Coatings and Paints

Working in manufacturing, you notice certain chemicals that pop up across different shop floors. 2-Ethylhexyl acetate gets used more than most people think, especially in paint and coatings. Walk down the aisle of an auto body shop, and this chemical is behind that glossy, durable finish on cars. Its slow evaporation helps prevent issues like uneven coat or streakiness, which are every painter’s headache. Factories rely on it for industrial coatings that stick firmly to steel and aluminum, crucial for everything from home appliances to farm equipment. In my time assisting with industrial safety audits, I’ve seen how vital it is for workers to know exactly what they’re spraying — both for quality and their own health.

Key Ingredient in Printing Inks

The printing world demands inks that dry at just the right speed. Too fast, and you’ll see smudging and set-off; too slow, and sheets feed into the next stage tacky and ruined. 2-Ethylhexyl acetate solves this with its steady evaporation rate and solvency power. In packaging plants I’ve toured, operators trust their presses to print clean graphics on everything from cereal boxes to shipping materials. Without a chemical like this, print jobs either bog down in delays or waste money on spoiled rolls.

Role in Adhesives and Sealants

Anyone fixing up an old house or working in a woodshop comes across adhesives that must cling tightly and set right. Here, 2-ethylhexyl acetate helps dissolve and carry the sticky stuff, making it spreadable without acting harsh on the base materials. In construction, this solvent helps adhesives last through heat, rain, and years of heavy use. Talks with carpenters and flooring installers show how much they count on proper adhesive performance — weak bonds mean call-backs and unhappy customers.

Active in Cleaning and Degreasing Formulas

The chemical’s grease-cutting ability lands it in many industrial cleaning products I’ve seen on plant tours. It breaks down oily residues on machine parts so that workers can keep things moving without dealing with sticky, grime-caked tools. Janitorial staff—especially in places like food factories—need reliable degreasers that won’t leave toxic traces or damage surfaces. Regular maintenance using these cleaning agents keeps equipment from breaking down early, which pays off on the factory floor.

Potential Hazards and Safer Use

Most places storing or using 2-ethylhexyl acetate have safety data sheets posted on the wall. Even though it’s less hazardous than some old-school solvents, inhaling too much vapor or letting it touch your skin can cause problems. I’ve seen facilities moving toward better local exhaust, gloves, and air monitoring to protect their workers, in line with modern safety regulations. Industry leaders stay on top of research into safer alternatives and keep staff informed about the risk, which builds trust.

A Chemical With Staying Power

2-Ethylhexyl acetate keeps showing up in products because it works — paints go on smoother, inks print sharper, adhesives last longer, and industrial spaces get cleaner. Its track record across so many sectors comes down to reliability and a chemical profile suited for real-world demands. I’ve seen firsthand how small tweaks with solvents can make a world of difference for production uptime and end results. Companies investing in greener ways to use or substitute it stand to build on its reputation while meeting today’s standards for health and environmental care.

| Names | |

| Preferred IUPAC name | 3-methyloctyl ethanoate |

| Other names |

Acetic acid 2-ethylhexyl ester

2-Ethylhexyl ethanoate Ethylhexyl acetate Acetoxyoctane |

| Pronunciation | /tuː ˌɛθ.ɪlˈhɛk.sɪl ˈæs.ɪ.teɪt/ |

| Identifiers | |

| CAS Number | 103-09-3 |

| Beilstein Reference | 1721739 |

| ChEBI | CHEBI:77703 |

| ChEMBL | CHEMBL3237233 |

| ChemSpider | 6826 |

| DrugBank | DB14663 |

| ECHA InfoCard | 13bc1965-03ab-4dc0-9ecd-8bfbb5ba4867 |

| EC Number | 212-164-9 |

| Gmelin Reference | 1578 |

| KEGG | C19641 |

| MeSH | D000062231 |

| PubChem CID | 31254 |

| RTECS number | AH5075000 |

| UNII | DTL8Q9E60N |

| UN number | UN1173 |

| Properties | |

| Chemical formula | C10H20O2 |

| Molar mass | 186.29 g/mol |

| Appearance | Colorless liquid |

| Odor | Fruity |

| Density | 0.87 g/cm3 |

| Solubility in water | Insoluble |

| log P | 4.2 |

| Vapor pressure | 0.13 mmHg (20°C) |

| Acidity (pKa) | 8.0 |

| Magnetic susceptibility (χ) | -61.5·10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.415 |

| Viscosity | 1.8 mPa·s (at 20°C) |

| Dipole moment | 3.91 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 287.6 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -482.9 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -4181.7 kJ/mol |

| Hazards | |

| GHS labelling | GHS02, GHS07 |

| Pictograms | GHS02,GHS07 |

| Signal word | Warning |

| Hazard statements | H226, H315, H317, H319, H335 |

| Precautionary statements | P210, P243, P261, P264, P271, P280, P301+P312, P303+P361+P353, P304+P340, P305+P351+P338, P312, P337+P313, P370+P378, P403+P235, P501 |

| NFPA 704 (fire diamond) | 'NFPA 704: 1-2-0' |

| Flash point | 102 °C |

| Autoignition temperature | 415 °C |

| Explosive limits | 1.0% - 7.0% |

| Lethal dose or concentration | LD50 (oral, rat): 9,100 mg/kg |

| LD50 (median dose) | LD50 (median dose): Rat oral 6500 mg/kg |

| NIOSH | KG8575000 |

| PEL (Permissible) | Not established |

| REL (Recommended) | 35 mg/m3 |

| IDLH (Immediate danger) | IDLH: 500 ppm |

| Related compounds | |

| Related compounds |

Acetic acid

2-Ethylhexanol 2-Ethylhexyl nitrate Ethyl acetate Butyl acetate |